A Framework for the Future: Digital Factories x Manufacturing Network

Speed and quality meet advanced capabilities and volume pricing—all with one reliable manufacturing resource

Certification + Compliance

ISO 9001:2015 | ISO 13485:2016 | AS9100D | ITAR

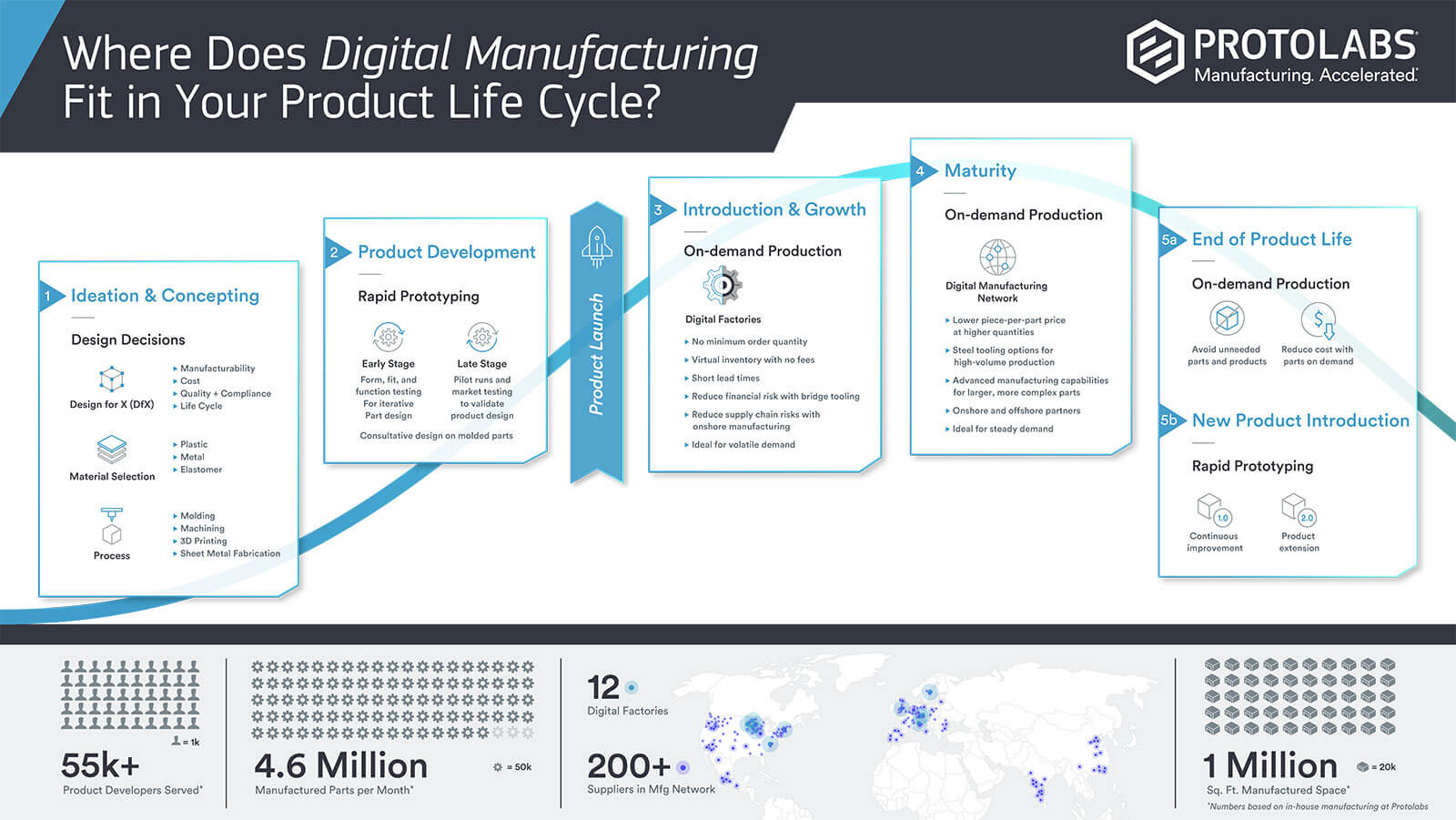

Why Digital Manufacturing?

Bring ideas to market with the fastest and most comprehensive digital manufacturing service in the world. Our digital factories produce low-volume parts in days while our digital network of manufacturing partners unlocks advanced capabilities and volume pricing at higher quantities. The result? One manufacturing source—from prototyping to production—for product developers, engineers, and supply chain teams across the globe.

What is Digital Manufacturing?

End-to-end manufacturing from quoting to production to shipping, inclusive of our in-house digital factories and our digital network of manufacturing partners

Enhanced Manufacturing Capabilities with Our Digital Network

Our digital network of manufacturers unlocks expanded capabilities across services. To move injection molding from low-volume (10,000+ parts) to higher-volume (100,000+ parts) production, try our network. Anodizing and tighter tolerances are available with CNC machining. And both molding and machining have volume pricing options for lower piece-part cost. You can even prototype quick and cost-efficiently with FDM 3D printing. Get more out of manufacturing with our digital network.

Try Protolabs NetworkWhat manufacturing services do

Protolabs’ factories and its network provide?

|

Factory Molding Our digital factories produce affordable, high-quality molded parts and bridge tooling within days. And with our free moldability consultation, the design and molding process is rapidly accelerated saving time and money.

|

Network Molding Our digital network opens up molding capabilities for larger, and more complex parts in higher-volume production quantities.

|

|

Factory Machining With hundreds of in-house CNC machines, our digital factories have infinite capacity to ensure parts are shipped on-time, every single time.

|

Network Machining Our digital network expands our machining capabilities with tighter tolerances, volume pricing, and the ability to handle more complex parts.

|

Compare our machining services from prototyping to production.

|

Factory 3D Printing We have the largest additive manufacturing operation in the world (U.S. and Germany) for functional prototyping and end-use production of quality 3D-printed parts.

|

Network 3D Printing We build cost-efficient 3D-printed prototypes and end-use parts built with fused deposition modeling (FDM). Customer can choose from a wide material and color selection for repeatable and precise parts within days.

|

|

Factory Sheet Metal Fabrication We have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every time—whether you need a single part or 500 parts.

|

Network Sheet Metal Fabrication Our digital network is ideal for small, production-grade sheet metal parts for concepts, prototypes, pre-production validation, and small run series.

|

Navigating the Numbers Behind Digital Manufacturing

Follow the digital thread for a look at the data inside a reinvented industry model that pairs our technology-enabled factories with a global network of manufacturers at Hubs.

Download InfographicHow do I order parts through Protolabs Network?

You can unlock Protolabs Network in two quick ways. When you have a quote from Protolabs, look for the network option inside your quote (currently, machining quotes only), which transfers you directly to our network of manufacturing partners at Hubs. You can also just head to hubs.com to quote and order directly through Protolabs Network.