Digital Manufacturing for Automotive Product Development

Conquer ever-shortening development cycles for traditional, electric, and autonomous vehicles with rapid prototyping and low-volume production

shield_locked All Uploads are Secure and Confidential

Certifications ISO 9001 | ISO 14001 | ISO 13485 (Protolabs Network) | DNV Qualification of Manufacture for Inconel 718 | JOSCAR

| Trusted By |  |

|

|

|

|

Challenges faced by the automotive industry

Customer success stories from the automotive industry

FAQs for automotive parts manufacturing

What materials work best for automotive parts manufacturing?

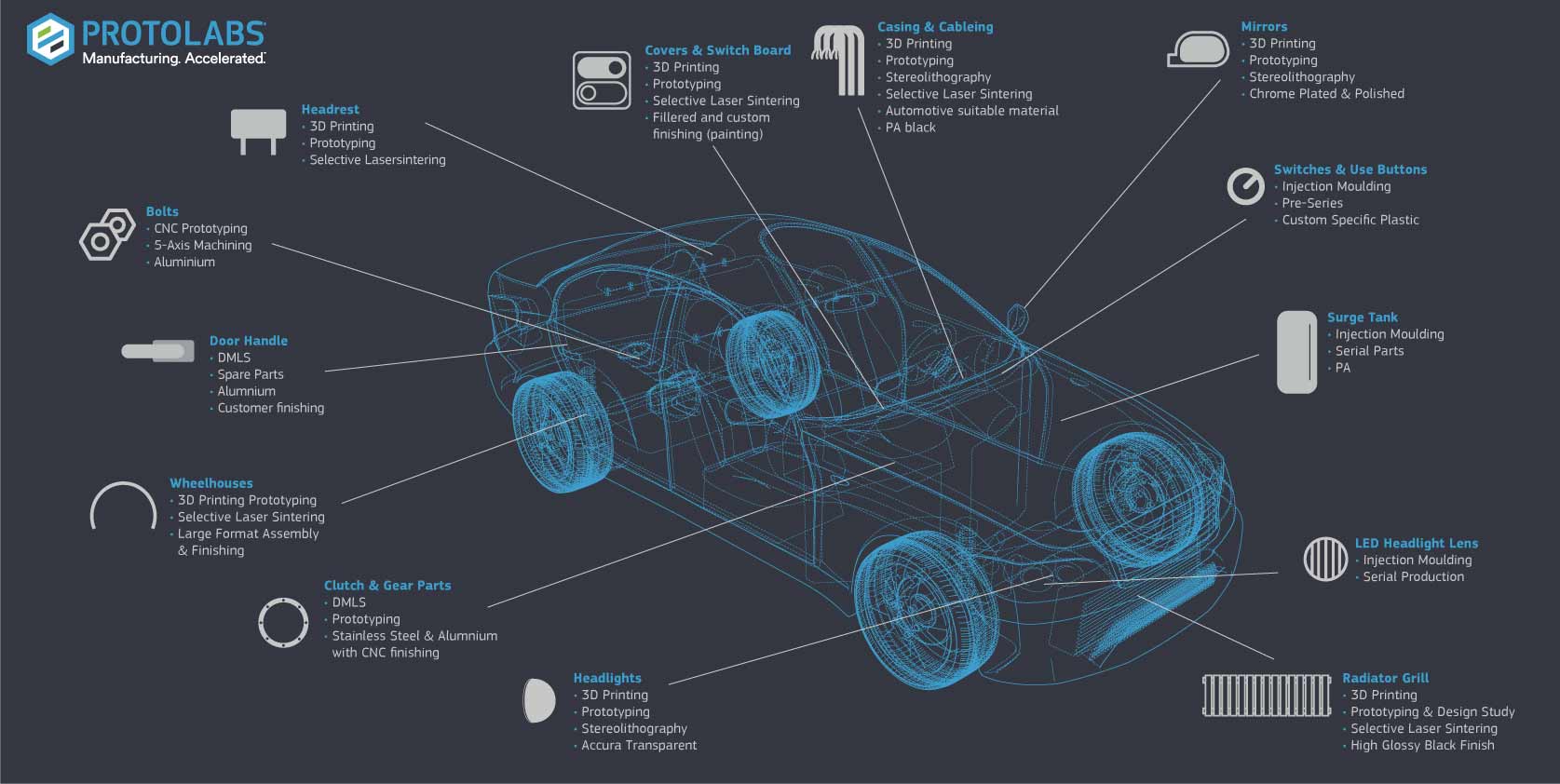

What are the applications of digitally manufactured parts for the automotive industry?

Why manufacturers of automotive products use Protolabs?

Amidst the dynamic landscape of the automotive sector, recent years have been defined by unprecedented challenges and fluctuating circumstances. However, amidst these trials, there are signs of resilience and progress, instilling a fresh wave of confidence and positivity.

Now more than ever, the imperative for adaptability and responsiveness is crystal clear. The automotive industry is in a transformative phase, characterised by the ascent of autonomous driving, seamless onboard connectivity, and the burgeoning popularity of hybrid and electric vehicles. The prevailing ethos revolves around expediting new product development and securing a competitive edge in the marketplace.

With Protolabs at their side, designers and engineers mitigate design and cost-related risks and fortify their supply chain with enhanced agility. This agility empowers them to meet the burgeoning demand for bespoke vehicles, aligning with the expectations of both drivers and passengers alike, providing both automotive parts manufacturing and automotive prototyping services.

Why Protolabs for Automotive Development?

Supply Chain Diversification

Build a manufacturing safety net into your automotive supply chain that you can turn to during line-down situations or unplanned disruptions.

Rapid Prototyping

Mitigate design risk through rapid iteration and prototyping in production materials without sacrificing development speed in your race to reach the automotive market first.

Jigs and Fixtures

Improve manufacturing processes to create greater automation and streamlined automotive component assembly with custom fixturing.

Quality Inspections

Validate part geometry with several quality documentation options. Digital inspection, PPAP, and FAI reporting are available.

Automotive Materials

Choose from hundreds of production-grade plastics along with fuel- and optical-grade silicone rubber. A range of metal materials for end-use components are also available through our 3D printing, machining, and sheet metal services.

450,000+

parts produced for the Automotive Industry

each year.

190+

Automotive companies worked with each

year.

400,000+ IM parts made each year

20,000+ 3DP parts made each year

4,000+ CNC parts made each year

What are the applications of injection moulded parts in the automotive industry?

- Dashboard panels

- Centre consoles

- Grilles

- Headlamp housings

- Taillight lenses

- Fog lamp bezels

- Battery housings

- HVAC housings

- Brake system components

What are the applications of 3D printed parts in the automotive industry?

- Tooling & Fixtures

- Personalised internal components

- Enclosures and Housings

- Brackets

- Hose and wire clips

- Lenses and lighting features

- Concept cars

- Showroom models

- Scale replicas

What are the applications of CNC machined parts in the automotive industry?

- Cylcinder heads

- Pistons

- Valves

- Camshafts

- Housings

- Clutch components

- Bushings

- Rotors

- Structural reinforcement

- Catalytic converters

Why manufacturers of Automotive products use Protolabs

A closer look at why Automotive companies are choosing Protolabs for automotive prototyping services and automotive parts manufacturing.

With injection moulding, you can achieve unparalleled precision and consistency in automotive parts manufacturing and automotive prototyping services, ensuring tight tolerances and uniformity across every part. Experience fast production cycles and reduced lead times, enabling you to meet tight production schedules and respond quickly to changes in demand. With a wide range of materials available, including thermoplastics, thermosets, and elastomers, you can select the perfect material for each component, ensuring optimal performance and durability. From high-volume production runs to low-volume custom projects. Injection moulding offers scalability and cost-efficiency, making it the ideal solution for automotive manufacturers seeking to enhance their competitiveness in the market.

- Scientific moulding, Critical to Quality (CTQ) capability report, Coordinate-Measurement Machines (CMM) and more

- Maximise traceability of raw materials from prototyping to production, with clear lines of sight over inventory, such as serial numbers for resin used in injection moulding.

- Digital front-end and automated workflows to improve part management.

- Lower setup costs with more cost-effective, standardised tooling to reduce outlay and delay

- Utilise our Consultative Design Services at any stage of the process for expert engineering know how.

- Design for Manufacturability Analysis (DfMA), our propriety software analyses your part and often returns it in minutes. (May take up to 48 hours for more complex parts)

- Variety of Thermosets and Thermoplastics - choose from hundreds of materials or provide your own material.

- Reduced Cycle Times

- Supply Chain Resilience - allowing for large-scale production or just-in-time production types.

- Rapid Prototyping and Iterative Design - enabling you to keep ahead of the competition

- Scalability and flexibility - allowing for ramping up production quickly whilst maintaining quality standards and meeting delivery times.

- Aluminium tooling - reduce cost and improve efficiency with aluminium tooling covered by our life-time guarantee when using our on-demand manufacturing service.

With CNC machining, you can achieve the highest level of accuracy and consistency in automotive parts manufacturing, ensuring optimal performance and reliability in every part. Experience fast turnaround times and efficient production cycles, enabling you to meet tight deadlines and rapidly iterate on designs. With a wide range of materials available, including metals, plastics, and composites, you can select the perfect material for each component, ensuring durability and longevity in even the most demanding automotive applications. Whether you're manufacturing engine components, transmission parts, or interior trim pieces, CNC machining offers the precision, flexibility, and efficiency you need to stay ahead in the competitive automotive industry.

- Wide variety of suitable materials, including a selection of Corrosion resistant, durable, strong, NVH dampening, and light-weighting materials.

- Benefit from out extended partner network - offering additional services and specifications (including additional certifications and post processing treatments).

- Numerous surface finishes and secondary services available such as; threading, anodising, assembly and much more

- Automotive prototyping services - offer fast iterative design for manufacturability, quick-turn parts for functional testing and design optimisation support whenever you require, to help you stay ahead of the competition

- Digital front-end and automated workflows to improve part management

- Quality assurance - ISO 9001:2015 certification for quality along with various quality control measures that can be included when producing your part.

- Industry-leading turnaround times - accelerated product development cycles

- Scalability - whether you are a small start-up or a large conglomerate, we have unlimited capacity to suport your requirements. Allowing you to seamlessly trasission from prototyping to full-scale production.

Revolutionise your automotive manufacturing process with the cutting-edge technology of 3D printing. Experience unparalleled design freedom and innovation as you bring your automotive components to life with precision and efficiency. With 3D printing, intricate geometries and complex shapes are no longer limitations but opportunities for optimisation and creativity. Rapid prototyping allows you to iterate quickly on designs, accelerating your product development cycle and bringing your vehicles to market faster than ever before. Whether you're looking to create lightweight yet durable parts, customise components for specific models, or produce low-volume batches with ease, 3D printing offers the flexibility and scalability you need to stay ahead in the competitive automotive industry.

- Certifications such as ISO 9001:2015, ISO 14001:2018, JOSCAR and DNV.

- A vast selection of materials, including corrosion resistant, conductive, temperature resistance/ conductivity, lightweighting and micro-resolution materials.

- A wide range of post-processing treatments including, powder analysis and material traceability, mechanical testing, heat treatments and much more.

- Sustainability - 3D printing is an additive manufacturing service, which automatically makes it more sustainable than its manufacturing alternatives. Only material required is added, rather than removing from a block and leaving waste

- Suitable for tailored products, low-volume, difficult to forecast products such as those requiring a Just-in-time approach.

- Advanced technologies - Protolabs leverages advanced 3D printing technologies including selective laser sintering and direct metal laser sintering to produce precise and detailed automotive parts with superior surface finishes and dimensional accuracy.

- Flexible prototyping for early developmental stages, easy to apply modifications on iterations.

- Tip-of-class surface finishes - Protolabs a variety of surface finishes including vapour smoothed surfaces, leather-look surface finishes, anodised parts, parts with machined surfaces, custom polished and much more.

- Customisation - due to flexibility and responsiveness of 3D printing parts can be produced as they are needed

- Complex and impossible geometries - when it comes to designing for 3D printed parts, the world is your oyster, there are no limitations.