3D Printing Services in New Industries

When we think of 3D printing services, our minds often turn to a handful of familiar areas, such as intricate medical devices, hi-tech automotive parts or rapid prototyping of products that are going to go into mass production. However, over recent years we’ve seen the advantages offered by this technology used in a wide variety of sectors and on a huge range of projects.

Just looking at our own list of case studies, we’ve had PepsiCo ask us to make incredibly detailed replicas of the Black Panther mask that could be attached to drink cans as part of a promotional campaign, and the beauty company IEVA use 3D printing to create their beautiful Twin-C smart jewellery. We’ve even used our tech to help make a range of printed clothing that made its way onto the red carpet at the Met Gala.

It’s easy to dismiss these projects as relatively unimportant, but in each example 3D-printing technology was chosen for the exact same reasons favoured by our industrial customers.

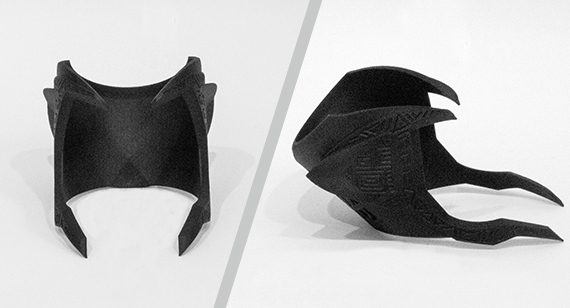

PepsiCo Black Panther Mask

When international food and beverages company PepsiCo wanted to produce a promotional mask to tie into the release of the Black Panther movie, they had a detailed list of product requirements.

- High levels of detail and quality

- Easily controllable design

- Economical to produce them in relatively small numbers (final run of 250 units)

Each of these requirements were something that 3D printing can achieve with relative ease.

Achieving incredibly high levels of detail is simple when you are able to create precise digital designs. These can ensure that features are correct right down to the micrometre, which is vital when you want a custom piece like the mask.

Making modifications to your design is also made much easier when the only thing you need to alter is a digital file. The nature of 3D printing means that moving a small piece of detail or altering the curve of a mask only requires tweaking a few numbers on a CAD file, rather than having to create new moulds or alter the machining.

Removing the need for moulds and machining also helps out with making low production runs feasible. The lack of a major up-front investment means that the overall cost per unit of a product remains similar whether you’re producing 250 units or 25,000 of them.

IEVA Smart Jewellery

When IEVA wanted to create parts for their range of Twin-C smart jewellery, they were attracted to 3D printing for two major reasons.

- High quality of finish

- Speed of design iteration

The quality of the finish is incredibly important for many applications, but this is particularly emphasised when it comes to jewellery. When you’re going to have an item on your wrist or hanging from your bag all day, it needs to look good, and this is something that the smooth, durable materials used in 3D printing are able to deliver in spades.

As well as this, the tactile, attractive nature of the product meant that IEVA’s designers needed to be able to see their prototypes in the real world and handle them directly before deciding on any alterations. More traditional production methods might have forced them to wait days or even weeks between iterations, but 3D printing is fast enough that they were able to get their hands on prototypes incredibly quickly.

This allowed them to ensure that every detail was perfect before the design was finalised.

Met Gala Dress

Fashion items may not seem the most obvious avenue for 3D printed materials, but when designer Zac Posen was dreaming up a dress for actress Nina Dobrev at the prestigious Met Gala, he took advantage of the technology to produce a beautiful clear bustier. This was helped by one important factor.

- Ignore limitations of traditional manufacturing

One of the great advantages of 3D printing technology is that it is not constrained by the need to allow tools in to cut a particular shape, or by having to support its own weight mid-build.

This means that designers are able to bump up the complexity of their designs without having to worry about practicalities of production. They are able to let their imaginations run wild, which is a potent tool in the hands of a fashion designer.

It seems that the ability to design and then produce pretty much anything you want using 3D printing is expanding its use into all sorts of unexpected areas.

For questions on any of our manufacturing services at Protolabs, please contact an applications engineer at customerservice@protolabs.co.uk or +44 (0) 1952 683047. Have a design ready for 3D printing? Upload it now for an instant quote.