What are the Rapid Prototyping Processes

How to select the best process for your project

Using rapid prototyping to manufacture parts to test for component fit and function can help get your product to market faster than your competition. Adjustments in design, materials, size, shape, assembly, colour, manufacturability, and strength can be made following the results of your testing and analysis.

Many rapid prototyping processes are available to today's product design teams. Some of these processes use traditional manufacturing methods, whereas others use techniques that are truly groundbreaking, but how is that so? In recent years we've seen new technologies emerge with capabilities that have transformed over a very short period. For today's engineers, this means there are dozens of ways prototypes can be made. So it goes without saying that as prototyping processes continue to evolve, product designers will have the constant challenge in determining which process (or technology) is best for their unique application. Continue reading to learn more.

This technical brief explores the advantages and shortcomings of the major prototyping processes available to designers. This paper provides detailed process descriptions and discusses material properties of parts produced by each specific prototyping process. In addition, a helpful decision tree highlights key questions designers must consider when choosing a prototyping process. Ultimately, the goal of this paper is to help you select the best prototyping process for your product development cycle.

Quick Reference Prototyping Process Comparison

| Process | Description | Strength | Finish | Example Materials | |

|---|---|---|---|---|---|

| SL | Stereolithography | Laser-cured photopolymer | 2,500 - 10,000 (psi) 17.2 - 68.9 (mpa) | Additive layers .051 - .152 (mm) typical | Thermoplastic-like photopolymers |

| SLS | Selective Laser Sintering | Laser-sintered powder | 5,300 - 11,300 (psi) 36.5 - 77.9 (mpa) | Additive layers .102 (mm) typical | Nylon, metals |

| DMLS | Direct Metal Laser Sintering | Laser-sintered metal powder | 37,700 - 190,000 (psi) | Additive layers .020 - .030 (mm) typical | Stainless steel, titanium, chrome, aluminiums, Inconel |

| FDM | Fused Deposition Modelling | Fused extrusions | 5,200 - 9,800 (psi) 35.9 - 67.6 (mpa) | Additive layers .127 - .330 (mm) typical | ABS, PC, PC/ABS, PPSU |

| 3DP | Three Dimensional Printing | Liquid binder inkjet printed onto powder | Low | Additive layers .089 - .203 (mm) typical | Plaster-based powder/liquid binder |

| PJET | Poly-Jet | UV-cured jetted photopolymer | 7,200 - 8,750 (psi) (psi) 49.6 - 60.3 (mpa) | Additive layers .015 - .030 (mm) typical | Acrylic-based photopolymers, elastomeric photopolymers |

| CNC | Computer Numerically Controlled (Machining) | Machined using CNC mills | 3,000 - 20,000 (psi) 20.7 - 137.9 (mpa) | Subtractive machined (smooth) | Most commodity and engineering-grade thermoplastics and metals |

| IM | Injection Moulding | Injection moulded using aluminium tooling | 3,100 - 20,000 (psi) 21.4 - 137.9 (mpa) | Moulded smooth (or with selected texture) | Most commodity and engineering-grade thermoplastics, metal and liquid silicone rubber |

| SL | Stereolithography |

|---|---|

|

SL is an additive fabrication process that builds parts in a pool of UV-curable photopolymer resin using a computer controlled laser. The laser is used to trace out and cure a cross-section of the part design on the surface of the liquid resin. The solidified layer is then lowered just below the surface of the liquid resin and the process is repeated. Each newly cured layer adheres to the layer below it. This process continues until the part is completed. SL was the first “rapid prototyping” technology. Pros

For concept models or patterns to be used as masters for other prototyping methods, SL can produce parts with complex geometries and excellent surface finishes as compared to other additive processes. The cost is very competitive and the technology is available from several sources ConsPrototype parts are not as strong as those made from engineering-grade resins, so the parts made using SL are typically unsuitable for functional testing. Also, since the resin is UV-curable, exposure to sunlight continues to cure the resin and parts can become brittle over time. |

| SLS | Selective Laser Sintering |

|---|---|

|

SL is an additive fabrication process that builds parts in a pool of UV-curable photopolymer resin using a computer controlled laser. The laser is used to trace out and cure a cross-section of the part design on the surface of the liquid resin. The solidified layer is then lowered just below the surface of the liquid resin and the process is repeated. Each newly cured layer adheres to the layer below it. This process continues until the part is completed. SL was the first “rapid prototyping” technology. Pros

SLS Parts tend to be more accurate and durable than SL parts. The process can make durable parts with complex geometries. ConsThe parts have a grainy or sandy texture and are typically not suitable for functional testing due to their reduced mechanical properties. |

| DMLS | Direct Metal Laser Sintering |

|---|---|

|

Direct metal laser sintering is an additive manufacturing technology that produces metal prototypes and production-quality parts. DMLS uses a laser system that draws onto a surface of atomised metal powder. Where it draws, it welds the powder into a solid. After each layer, a blade adds a fresh layer of powder and repeats the process. DMLS can use most alloys, allowing prototypes to be full-strength, functional hardware made out of the same material as production components. It also has the potential, if designed with manufacturability in mind, to transition into metal injection moulding when increased production if needed Pros

DMLS produce strong (typically, 97 percent dense) prototypes from a variety of metals that can be used for functional testing. Since the components are built layer by layer, it is possible to design internal features and passages that could not be cast or otherwise machined. ConsIf producing more than a few DMLS parts, costs can rise. Due to the powdered metal origin of the direct metal process, the surface finish of these parts are slightly rough.

|

| FDM | Fused Deposition Modelling |

|---|---|

|

The FDM process builds parts from the bottom up through the use of a computer-controlled print head. The feedstock for the process is a filament of extruded resin, which the machine selectively re-melts and deposits on the prior layer for each cross section of the desired part. The FDM process primarily produces parts in ABS or PC, so they tend to be stronger than parts from other additive processes. However, the parts are sometimes porous and have a pronounced stair-stepping or rippling texture on the outside finish, especially at layer junctions. It may also be difficult to achieve tight tolerances with the process. Pros

FDM parts are relatively strong and can be good for some functional testing. The process can make parts with complex geometries. ConsThe parts have a poor surface finish, with a pronounced rippled effect. It is also a slower additive process than SL or SLS from the standpoint of build time. |

| 3DP | Three Dimensional Printing |

|---|---|

|

In 3DP an inkjet print head moves across a bed of powder, selectively depositing a liquid binding material, and the process is repeated until the complete part has been formed. After completion, the unbound powder is removed leaving the finished object. Pros

3DP offers one of the fastest build time of any additive process, and is also among the least expensive options for prototype quantities. Coloured models can communicate more information and have aesthetic appeal. This plaster material is non-toxic, inexpensive, and readily available. The process can make parts with complex geometries. ConsParts are rough and weak, and there are very few material options. While 3DP can make parts with complex geometries, it gives no insight into the eventual manufacturability of the design. |

| PJET | Poly-Jet |

|---|---|

|

PJET uses inkjet heads to jet a UV-curable material in very thin layers at high resolution. The materials are jetted in ultra-thin layers onto a build tray, layer by layer, until the part is completed. Each photopolymer layer is cured by UV light immediately after it is jetted. The gel-like support material, which is specially designed to support complicated geometries, is easily removed by hand and water jetting. Pros

This process yields a good surface finish; one of the best of the additive processes. It is a good additive choice for complex parts with undercuts. The process can support complex geometries and parts with multiple materials and colours. ConsPJET parts have poor strength (comparable to SL). While PJET can make parts with complex geometries, it gives no insight into the eventual manufacturability of the design. |

| CNC Machining | Computer Numerically Controlled Machining |

|---|---|

|

A solid block of plastic or metal is clamped into a CNC mill and cut into a finished part through a subtractive process. This method produces superior strength and surface finish to any additive process. It also has the complete, homogenous properties of the plastic because it is made from solid blocks of extruded or compression moulded thermoplastic resin, as opposed to most additive processes, which use plastic-like materials and are built in layers. The range of material choices allows parts to be made with the desired material properties, such as: tensile strength, impact resistance, heat deflection temperatures, chemical resistance, and biocompatibility. Good tolerances yield parts suitable for fit and functional testing. Prototypes can be delivered in days like additive processes. Because the process is removing material instead of adding it, milling undercuts can sometimes be difficult. Machining also tends to be somewhat more expensive than the additive processes. Pros

Machined parts have a good surface finish and they are very strong because they use real engineering-grade thermoplastics and metals.

Cons There are some geometry limitations associated with CNC machining, and it is much more expensive to do this in-house than the additive processes due to the cost of the programmers and machinists needed to create CNC toolpaths and fixturing for the parts.

|

| IM | Injection Moulding |

|---|---|

|

Rapid injection moulding works by injecting thermoplastic resins into a mould, just as in production injection moulding. What makes the process “rapid” is the technology used to produce the mould, which is often made from aluminium instead of the traditional steel used in production moulds. Moulded parts are strong and can have excellent finishes. It is also the industry standard production process for plastic parts, so there are inherent advantages to prototyping in the same process if the situation allows. Almost any engineering-grade resin can be used, so the designer is not constrained by the material limitations of the prototyping process. Additionally, metal injection moulding (MIM) and liquid silicone rubber (LSR) moulding offer rapidly moulded parts in metals like stainless steel and LSR, respectively. |

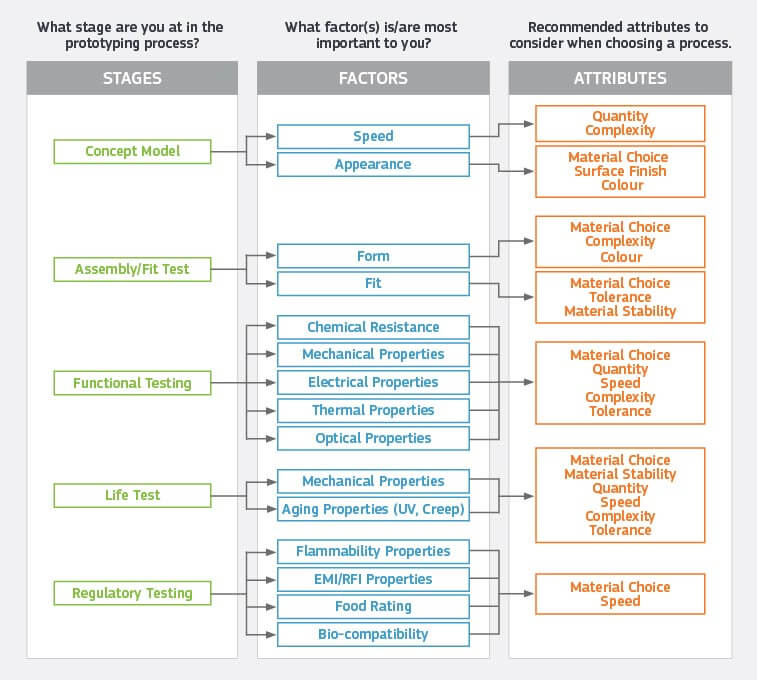

Choosing a Process

Determine the process that is the best fit for your project by using the tools shown here.

Step 1:

Begin by using the decision tree below to narrow down which factors are of highest importance to you based on the stage you are at in the prototyping process.

Step 2:

Based on the recommended attributes for your most important factor(s) from Step 1, compare the processes using the matrix to determine which process will be the best fit for your project.

Definitions

Definitions vary and may differ at different organisations, but the definitions below may be used as a starting point.

Concept Model – A physical model made to demonstrate an idea. Concept models allow people from different functional areas to see the idea, stimulate thought and discussion, and drive acceptance or rejection.

Important prototyping attributes:

Speed – turnaround time to convert a computer file into a physical prototype

Appearance – any visual attribute: colour, texture, size, shape, etc.

Assembly / Fit Test – making some or all of the parts of an assembly, putting them together, and seeing if they fit properly. At the gross level, this checks for design errors, such as placing two tabs at 2 in. spacing and the mating slots at 1 in. spacing. At the fine level, this is a matter of minor dimensional differences and tolerances. Obviously, any test involving tolerances needs to use the actual manufacturing process or one which has similar tolerances.

Important prototyping attributes:

Form – the shape of the part: features and size

Fit – how the part mates with other parts

Functional Testing – seeing how a part or assembly will function when subjected to stresses representing what it will see in its actual application.

Important prototyping attributes:

Chemical Resistance – resistance to chemicals including acids, bases, hydrocarbons, fuels, etc.

Mechanical Properties – strength of the part measured by tensile strength, compressive strength, flexural strength, impact strength, tear resistance, etc.

Electrical Properties – interaction of electrical fields and the part. This may include dielectric constant, dielectric strength, dissipation factor, surface and volume resistivity, static decay, etc.

Thermal Properties – changes in mechanical properties that occur with changes in temperature. These may include thermal expansion coefficient, heat deflection temperature, vicat softening point, etc.

Optical – ability to transmit light. May include refractive index, transmittance and haze.

Life Test – testing properties that may change with time and that are important for a product to remain functional throughout its expected life. Life testing often involves subjecting the product to extreme conditions (e.g. temperature, humidity, voltage, UV, etc.) to estimate in a shorter period of time, how the product will react over its expected life.

Important prototyping attributes:

Mechanical Properties – fatigue strength: ability to withstand large numbers of load cycles at various stress levels.

Aging Properties (UV, creep) – ability to withstand exposure to ultraviolet light with an acceptable amount of degradation; ability to withstand extended applications of forces to the part with acceptable levels of permanent deflection.

Regulatory Testing – testing specified by a regulatory or standards organisation or agency to assure parts are suitable for a particular use such as medical, food service or consumer application. Examples include Underwriters Laboratory (UL), the Canadian Standards Association (CSA), the US Food and Drug Agency (FDA), the US Federal Communications Commission (FCC), the International Standard Organisation (ISO) and the European Commission (EC).

Important prototyping attributes:

Flammability Properties – the resistance of a resin or part to ignition in the presence of a flame.

EMI/RFI Properties – the ability of a resin, part or assembly to shield or block Electromagnetic Interference or Radio Frequency Interference.

Food Rating – approval of a resin or part to be used in applications where it will come in contact with food while it is being prepared, served or consumed.

Bio-compatibility – the ability of the resin or part to be in contact with human or animal bodies, outside or inside the body, without causing undue adverse effects (e.g. irritations, blood interactions, toxicity, etc). Bio-compatibility is important for surgical instruments and many medical devices.

Summary

Prototype models help design teams make more informed decisions by obtaining invaluable data from the performance of, and the reaction to, the prototypes. The more data that is gathered at this stage of the product development cycle, the better the chances of preventing potential product or manufacturing issues down the road. If a well thought out prototyping strategy is followed, there is a far greater chance that the product will be introduced to the market on time, be accepted, perform reliably, and be profitable.

What is the best way to get a prototype made? The answer depends on where you are at in your process and what you are trying to accomplish. Early in the design process, when the ideas are flowing freely, concept models are very helpful. As the design progresses, a prototype that has the size, finish, colour, shape, strength, durability, and material characteristics of the intended final product becomes increasingly important. Therefore, using the right prototyping process is critical. In order to most effectively validate your design, pay close attention to these three key elements of your design: functionality, manufacturability, and viability.

If your prototype can faithfully represent the attributes of the end-product, it is by definition functional. These requirements often include such things as material properties (e.g. flame resistance), dimensional accuracy for fit-up with mating parts and cosmetic surface finishes for appearance.

If your prototype design can be repeatedly and economically produced in a manner that supports the requirements of the end-product, it is by definition manufacturable. These requirements include the ability to maintain the functionality of the design as described above, keep the piece-part cost below the required level, and support the production schedule. No matter how great a design is, it will go nowhere if it can’t be manufactured. Make sure your prototyping process takes this into consideration.

Finally, even if your prototype design is functional and manufacturable, it doesn’t mean anyone will want to use it. Prototypes are the only true way to verify the viability of the design in this sense. If your design can also pass the challenges associated with market trials (e.g., trade show displays, usability testing) and regulatory testing (e.g., FDA testing of medical devices), you’re well on your way to a successful product launch.

-