Protolabs Product Release Notes

Discover our latest product releases, capability enhancements, and e-commerce upgrades

*EMEA Only

New Selective Laser Sintering Materials - PAx Smooth Natural & PAx Vapour Smooth Natural

We've added PAx Smooth Natural and PAx Vapour Smooth Natural to our Selective Laser Sintering offering. Characterised by excellent toughness and flexibility in any direction (including the z plane)

Primary Benefits include;

- Excellent toughness and durability

- High impact and high elongation

- Long-term stability

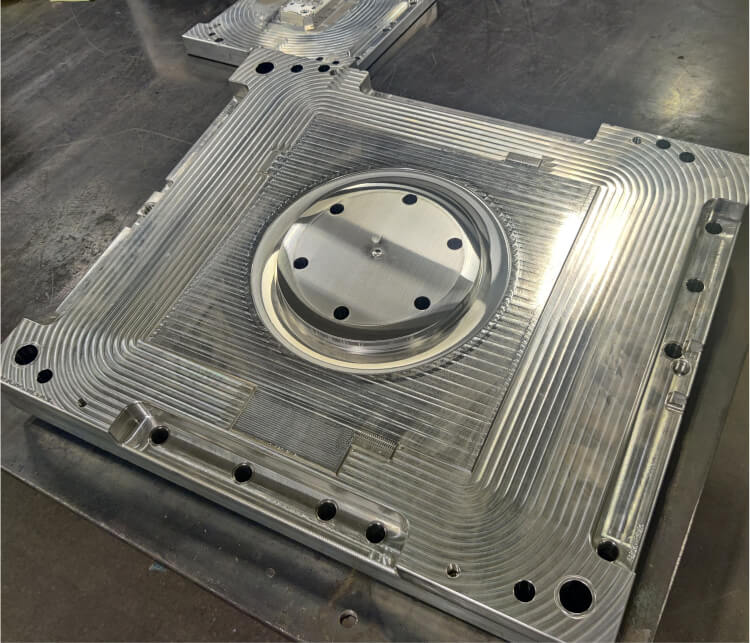

Improved Polishing Capabilities Without Sacrificing Lead Times

We are constantly looking for innovative ways to improve - with our new proprietary mill head auto polishing system, we can get customer products (parts) out the door faster. We now offer auto polishing of mould surfaces, with continued focus to make that even more efficient in the future. We are ultimately producing higher quality finishes, saving labour time and costs.

New Multi Jet Fusion Material PA12 Glass Beads Smooth Grey

We’ve added PA 12 Glass Beads Smooth Grey to our Multi Jet Fusion offering, meaning you can create quality, strong parts for prototyping and end-use products. The high-strength nylon exhibits a quality surface finish and is water and air-tight without additional treatment.

This material possesses several advantages when produced with Multi Jet Fusion:

- Consistent mechanical properties near isotropic

- Finer details with a minimum feature size of 0.5 mm

- Increased heat deflection temperature up to 175°C

Get Rapid 5-axis Inedexed Milled Parts

We constantly challenge ourselves to improve our offerings to you. As part of that commitment, you can

now get bigger, more complete parts across a range of materials in as little as 1 to 3 days with our 5-axis

indexed milling capabilities.

The result?

- 150% larger envelope for parts requiring 5-axis machining

- Reduction in unreachable material, averaging a 13% improvement in plastic parts

- More complex geometries and non-orthogonal features like off-axis holes are now machinable

Injection Moulding Recycled Materials

In today’s world, where sustainability is a pressing global concern, the need for greener manufacturing practices has never been more crucial. Protolabs now offers three recycled materials for its injection moulding service.

Compare Recycled Materials to their Traditional Counterparts

New 3D Printing Leather Surface Finish

Finish your parts with a flawless, uninterrupted pattern!

When 3D printing parts, our engineers can translate images of a pattern directly to the surface of your part, resulting in a visually stunning and tactile pattern. Not only does it look amazing, but control over surface structure provides opportunities for

ergonomics, functionality and customisation.