Redefining Surface Quality 3D Printed Parts

Improved surface roughness finishes on our powder-based plastics for functional prototyping and end-use parts

The surface roughness of your 3D-printed parts dramatically affects how they will interact with the real-world environment. From cracks and adhesion, to contact stiffness and static friction, the surface roughness is a great indicator of what your part will look like and how your part will perform – But not all parts require the same level of performance.

Protolabs has redeveloped our surface quality standards for MJF and SLS produced parts, delivering a best-in-class finish through flexible surface roughness options. Now you can select the appropriate surface finish that your part requires, with the quality service that you expect from Protolabs.

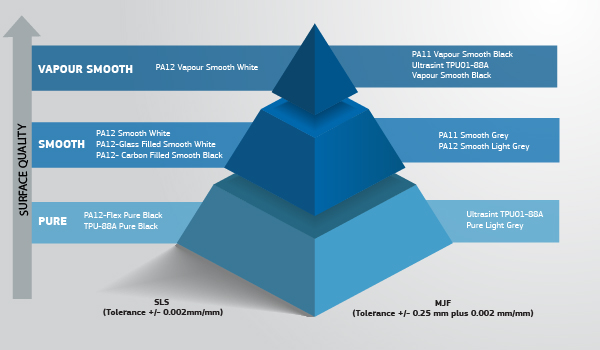

Pure, Smooth, Vapour Smooth

Protolabs has redeveloped our surface quality standards for MJF and SLS produced parts, delivering a best-in-class finish through flexible surface roughness options. Now you can select the appropriate surface finish that your part requires, with the quality service that you expect from Protolabs.

Pure

Our base option delivers a pure finish, with surface roughness as expected from a high-quality 3D-Printed part. We bead blast parts to remove all powder, leaving a consistent overall texture. Only available for some materials.

Smooth

Our standard option delivers a smooth finish with reduced surface roughness, delivering value far beyond the standards we have ever offered. This is what you receive as a default option for most materials.

PA 12 Smooth Light Grey (MJF)

PA 11 Smooth Grey (MJF)

PA12 Smooth White (SLS)

Vapour Smooth

Our premium option delivers a vapour smooth finish, offering a finish close to what you usually associate with Injection Moulding, but on a 3D-Printed part. We treat parts through an automated, high-quality post-processing technique, which leaves them with great aesthetics and sealed surfaces that are water and air-tight and easy to clean.

PA11 Vapour Smooth Black (MJF)

A change for the better

Our new surface finish system means that you get more value than ever before. Smooth is now our standard finishing option, a far superior surface finish to what we previously offered as standard.

The improvement in surface roughness is significant and is evident when comparing PA 12 Smooth white vs Previous PA 12 White in SLS:

Ra = 10 - 25 µm, down from 15 – 30 µm

Rz = 60 – 140 µm, down from 90 – 160 µm

The three levels of surface quality finish visually explained:

| ROUGHNESS | ||||

| Ra Min [µm] | Ra Max [µm] | Rz Min [µm] | Rz Max [µm] | |

| MJF Ultrasint TPU01-88A Pure Grey | 20 | 30 | 120 | 160 |

| SLS PA12 Smooth white | 10 | 25 | 60 | 140 |

| SLS PA12-GF Smooth white | 10 | 25 | 60 | 120 |

| MJF PA12 Smooth Light Grey | 10 | 25 | 60 | 100 |

| MJF PA11 Smooth Grey | 10 | 25 | 60 | 100 |

| SLS PA12 Vapour Smooth white | 5 | 15 | 25 | 65 |

| MJF PA11 Vapour Smooth Black | 5 | 10 | 20 | 45 |

| MJF Ultrasint TPU01-88A Vapour Smooth Black | 2 | 8 | 8 | 25 |

With the new Smooth finish, MJF parts in PA 12 and PA 11 are now light grey and grey, respectively. The colour is uniform, and the undyed parts are biocompatible.

Furthermore, untreated material is certified according to the following standards:

UL 94 (Standard for Safety of Flammability of Plastic Materials for Parts Devices and Appliances testing)

UL 746A (Standard for Polymeric Materials to measure Short Term Property Evaluations)

If you still need black dyed parts, we now offer a production quality dyeing process, which is much more long-lasting and of better quality than before. The new process provides many improvements around scratch resistance, light and heat resistance, colour fastness and skin irritation. The following certifications are available:

Biocompatability

Cytoxcity

✓ ISO 10933-5

✓ ISO 10933-12

Skin Irritation

✓ ISO-Protocol ISO/ TC 194 WG8

✓ ISO 10933-12

Colour Fastness

✓ Rubbing: ISO 105-X12

✓ Washing: ISO 105-C06

✓ Bleaching: 20105-N01

✓ Perspiration: ISO 105-E04

Scratch Resistance

✓ PV3952

Light & Heat Resistance

✓ ISO 105 B06

Finally, Vapour Smooth finish is now available for PA 11 in MJF! You can now get great looking, ultra smooth, sealed PA 11 MJF parts, which present a very appealing shiny black colour.