Stereolithography (SLA)

SLA 3D printing service for rapid prototyping. Get an instant online quote.

shield_locked All Uploads are Secure and Confidential

Stereolithography (SLA) is an industrial 3D printing process used to create concept models, cosmetic prototypes, and complex parts with intricate geometries in as fast as 1 day. A wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SLA.

SLA 3D printing is primarily used for:

- parts requiring high accuracy and features as small as 0.07mm

- good surface quality for cosmetic prototypes

- form and fit testing

SLA Design Guidelines & Capabilities

Our basic guidelines for stereolithography include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

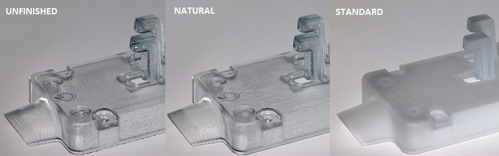

3D Printing Surface Finish Guide

Our 3D Printing surface finish guide provides you with a quick overview of our finishing options and what you can expect when your 3D-printed parts arrive.

3DP Surface Finishes Guide

SLA Material Options

Below are your SLA material options at Protolabs. We offer a wide range of thermoplastic-like materials as well as post-processing options to enhance cosmetics and material attribute. Note that each property listed is measured along the X-Y plane.

ABS-Like White (Accura Xtreme White 200)

expand_less expand_moreABS-Like White (Accura Xtreme White 200) is a widely used general purpose SLA material. In terms of flexibility and strength, this material falls between moulded polypropylene and moulded ABS, which makes it a good choice for functional prototypes. Parts as large as 736mm x 635mm x 533mm can be built with ABS-Like White so consider it a primary option if you require an extensive part size build envelope.

Primary Benefits

- Durable, general purpose resin

- Accommodates extra-large parts

ABS-Like Grey (Accura Xtreme Grey)

expand_less expand_moreABS-Like Grey (Accura Xtreme Grey) is a widely used general purpose SLA material. In terms of flexibility and strength, this material falls between moulded polypropylene and moulded ABS, which makes it a good choice for functional prototypes. ABS-Like Grey offers the highest HDT of the ABS-like SLA resins.

Primary Benefits

- Durable, general purpose resin

- Highest HDT of the ABS-like SLA resins

ABS-Like Black (Accura Black 7820)

expand_less expand_moreABS-Like Black (Accura Black 7820) is a widely used general purpose material. Its deep black colour and glossy up-facing surfaces in a top profile offer the appearance of a moulded part, while layer lines may be visible in a side profile. Accura Black 7820 also has low moisture absorption (0.25% per DIN EN ISO 62) so that parts are more dimensionally stable. Compared to other SLA materials, it has midrange values for all mechanical properties.

Primary Benefits

- Low moisture absorption

- Glossy cosmetic appearance

ABS-Like Translucent/Clear (WaterShed XC 11122)

expand_less expand_moreABS-Like Translucent/Clear (WaterShed XC 11122) offers a unique combination of low moisture absorption (0.35% per DIN EN ISO 62) and near-colourless transparency. Secondary operations are required to achieve functional part clarity, and the part will also retain a very light blue hue afterward. While good for general-purpose applications, WaterShed is the best choice for flow-visualisation models, light pipes, and lenses.

Primary Benefits

- Lowest moisture absorption of SLA resins

- Functional transparency

MicroFine™ Green

expand_less expand_moreMicroFine™ is a custom formulated material available in green that is exclusive to Protolabs. This ABS-like thermoset is printed in Protolabs’ customised machinery to achieve high resolution features as small as 0.05mm MicroFine is ideal for small parts, generally less than 25.4mm by 25.4mm by 25.4mm In terms of mechanical properties, MicroFine falls in the mid-range of SLA materials for tensile strength and modulus and on the low end for impact strength and elongation.

Primary Benefits

- Produces highest resolution parts

- Ideal for extra-small parts

PC-Like Advanced High Temp (Accura 5530)

expand_less expand_morePC-Like Advanced High Temp (Accura 5530) creates strong, stiff parts with high temperature resistance. A thermal post-cure option can increase HDT as high as 250°c at 0.46 MPa loading. Accura 5530 has the highest E-modulus of all the unfilled SLA materials, and it is known for being resistant to automotive fluids. However, the thermal curing process does make Accura 5530 less durable, resulting in a 50% reduction to elongation.

Primary Benefits

- High elastic modulus

- Higher resistance to heated fluids

Ceramic-Like Advanced High-Temp (PerFORM)

expand_less expand_moreCeramic-Like Advanced HighTemp (PerFORM) exhibits the highest tensile strength and E-modulus making it the stiffest performance material of the SLA materials. When the thermal cure option is applied to parts made from PerFORM, it exhibits the highest HDT (as high as 268°C at 0.46 MPa loading) of the SLA materials.

Primary Benefits

- Stiffest SLA resin

- Highest HDT of SLA resins

Compare Material Properties

| Material | Colour | Tensile Strength (x-y plane) | E-module (x-y plane) | Elongation at break (x-y plane) |

|---|---|---|---|---|

| ABS-Like White (Accura Xtreme White 200) |

White | 55 MPa ± 10 MPa | 3300 MPa ± 400 MPa | 5% ± 5% |

| ABS-Like Grey (Accura Xtreme Gray) |

Grey | 40 MPa ± 8 MPa | 2000 MPa ± 400 MPa | 9% ± 5% |

| ABS-Like Black (Accura 7820) |

Black | 55 MPa ± 10 MPa | 3000 MPa ± 400 MPa | 5% ± 3% |

| ABS-Like Translucent/Clear (WaterShed XC 11122) | Translucent/Clear | 55 MPa ± 10 MPa | 2900 MPa ± 400 MPa | 6% ± 3% |

| MicroFine™ Green |

Green | 60 MPa ± 10 MPa | 2600 MPa ± 400 MPa | 8% ± 4% |

| PC-Like Advanced High Temp* (Accura 5530) | Translucent/Amber | 45 MPa ± 10 MPa | 3900 MPa ± 400 MPa | 1.5% ± 1% |

| Ceramic-Like Advanced HighTemp* (PerFORM) |

White | 75 MPa ± 10 MPa | 10,500 MPa ± 1000 MPa | 1% ± 0.5% |

*Properties listed are based on thermal cure

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

Resources

About Stereolithography

What is Stereolithography?

expand_less expand_more

Stereolithography is a 3D Printing process which uses a computer-controlled moving laser beam, pre-programmed using CAM/CAD software.

Stereolithography (SL) is an industrial 3D printing process used to create concept models, cosmetic - rapid prototypes, and complex parts with intricate geometries in as fast as 1 day. Stereolithography parts can be produced in a wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SL. We also offer a number of secondary services such as painting, post machining and measurement and inspection, to further enhance the finish of your 3D-printed project design.

Stereolithography design guidelines will help you understand capabilities and limitations.

Why choose Stereolithography?

expand_less expand_moreStereolithography (SL) is an excellent choice for rapid prototyping and project designs that require the production of very accurate and finely detailed parts. It’s ideal for producing show-and-tell parts to enable validation of concept ideas and ergonomic testing. We also offer a number of secondary services such and plating and painting to further enhance the finish of your 3D-printed project design.

Stereolithography material data sheets can be found in our Material Comparison Guide

How does Stereolithography Work?

expand_less expand_moreHow Does Stereolithography Work?

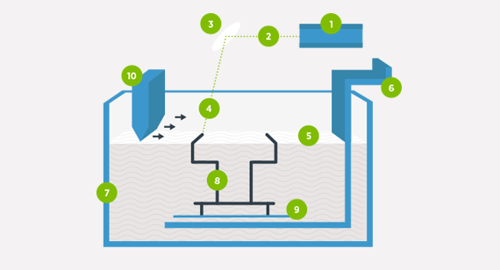

The components of a SLA 3D printer include: laser unit (1), laser beam (2), mirror/galvo motor system, beam steering (3), focused & directed Beam (4), resin surface (5), elevator (6), vat (7), part pattern (8), build platform (9), recoater blade (10).

The SL machine begins the 3D printing process by drawing the layers of the support structures, followed by the part itself, with an ultraviolet laser aimed onto the surface of a liquid thermoset resin. After a layer is imaged on the resin surface, the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. The process is repeated layer by layer until the build is complete.

Newly built parts are taken out of machine and into a lab where solvents are used to remove any additional resins. When the parts are completely clean, the support structures are manually removed. From there, parts undergo a UV-curing cycle to fully solidify the outer surface of the part. The final step in the SL process is the application of any custom or customer-specified finishing. Parts built in SL should be used with minimal UV and humidity exposure so they don’t degrade.

Benefits of Stereolithography

expand_less expand_moreBenefits of Stereolithography

- Competitively priced

- Excellent surface finish

- Easily duplicates complex geometries

- One of the best surface finishes for an additive process

What is Stereolithography used for?

expand_less expand_moreWhat is Stereolithography Used for?

Stereolithography is good for producing accurate prototypes and models.

Stereolithography is well used for creating accurate 3D models of anatomical regions of a patient, used to aid in diagnosis and for pre-planning and implant design and manufacture. It is also good for use in concept models and scale models.

Stereolithography is used for prototyping in order to assess design and for part validation. This is due to accuracy and its ability to produce irregular shapes.

To see an example of a part worked on by Protolabs that used our Stereolithography service, please click here.

3D printing at Protolabs

In this short video, we explain the three 3D printing services available at Protolabs, using footage taken from our global facilities. We offer three advanced processes: stereolithography (SL), selective laser sintering (SLS) and direct metal laser sintering (DMLS), which can build either plastic or metal parts with different advantages to each.

Our major differentiator is the scale of our industrial 3D printing production capabilities. Our 3D printing service is fast, supported by our industrial-grade processes, repeatability, and range of materials.