Injection Moulding Quality Control and Standards

How we use digital processes, scientific moulding, and inspection reporting to manufacture quality parts consistently

Certifications ISO 9001:2015 | AS9100D | ITAR Registered

Inspections for Injection-Moulded Parts

We offer several quality inspection reports for injection moulding orders. Depending on your project requirements you can choose from the following reports:

- CTQ Partial FAI

- CTQ DIR with Capability Study

- Production Part Approval Process (PPAP)

- Digital Inspection Report / Full FAI

- Custom Inspection

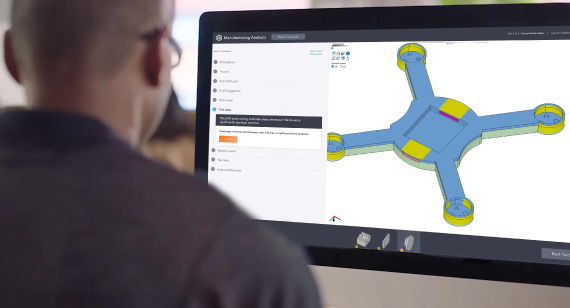

Design for Manufacturing (DFM) Analysis

When requesting a quote through our online quoting system, you will receive manufacturing analysis and pricing. The first step in the digital manufacturing process can enable customers to test multiple designs simultaneously, thereby arriving to design validation sooner, which saves time in the development cycle.

How our manufacturing analysis can improve the quality of injection-moulded parts:

- Identifies thick walls

- Identifies features with insufficient draft

- Select gate location

- Select the ejector pin location

Design Support from Injection Moulding Experts

Consultative Design Services: Work directly with an injection moulding applications engineer to improve the mouldability of your design. Think of it like having your very own injection moulding consultant on your team. During this process, our applications engineer will collaborate with you to understand your design goals, review the manufacturing analysis provided in your online quote, and make changes to the 3D CAD file.

Protolabs Proposed Revision (PPR): In some instances, we can provide a second CAD model to you—called a Protolabs Proposed Revision (PPR). This is a new CAD file with changes already made. The revised model can be used immediately or you can transfer the modifications to the original model. Following the DFM analysis, and, in some cases, the PPR, once the part has been approved, Protolabs moves into the final step before actual production—the digital preparation

Scientific Moulding: Consistently Delivering Quality Parts

We use scientific, or decoupled injection moulding process to manufacture consistent, repeatable parts for our injection moulding customers. We develop, optimise, and document the ideal set up process for each injection moulding project so that the same process and parameters are followed for every single run of a customer's mould. Any modifications are documented to provide traceability across moulding runs.

Whether the part will be run again or on a different injection moulding press, or if it will be ordered once several months later, scientific moulding ensures part-to-part and run-to-run consistency by documenting the exact process used to set up the tool in order to meet the particular resin needs and dimensional requirements.

By following these industry best practices we can ensure that each part has the same properties as the previous part, by controlling fill, pack, and hold. This results in two key benefits for our customers: more consistent parts that are higher quality and inspection reports for qualification.