Developing a Product Strategy Around Industry 4.0

How to convert the economics of digital manufacturing into efficiencies, revenue, and profit to enable Product 4.0

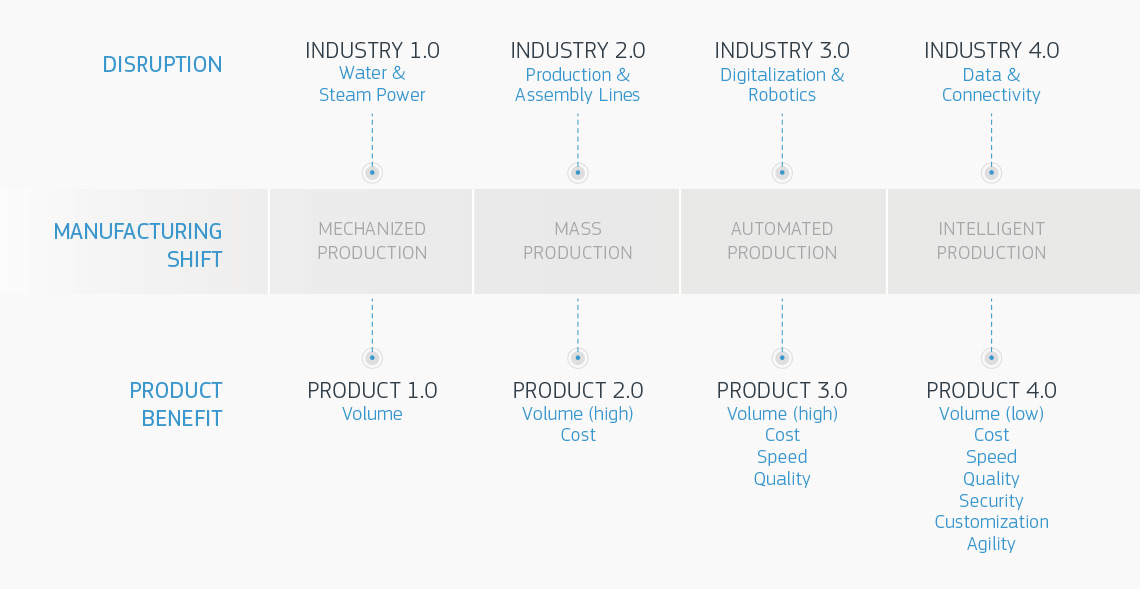

Industry 4.0 is the next major upheaval and progression for manufacturing. First mechanization (via water/steam), then assembly and production lines, followed by digitalization (analog to digital and robotics), this fourth revolution is a global megatrend reframing the capabilities and economics of modern manufacturing through data, automation, and technology. According to McKinsey, 35% of global manufacturers surveyed expect Industry 4.0 to drive 20% or more revenue growth over the next five years. Similarly about half expect to reduce costs and increase efficiency by 20% or more.

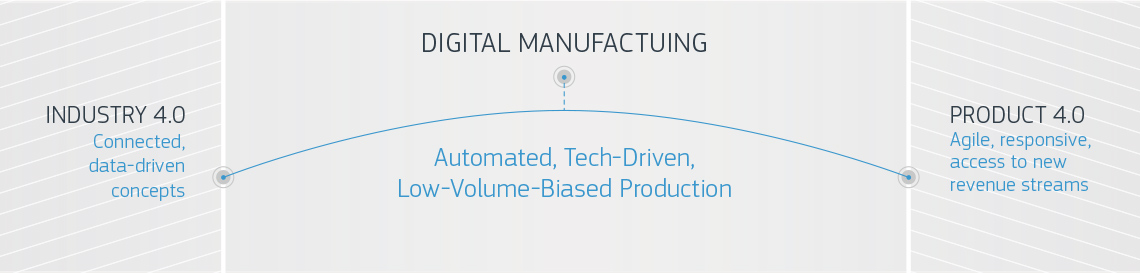

While conceived from applications centered on maintenance, repair, and internet of things (IoT) sensor arrays, the technologies and applications that power a digital manufacturing company have grown to have business benefits across factors such as time to market, labor and asset utilization, quality control, and inventory management. Moving from a macro to micro view, we assert then that digital manufacturing is seeding the new economics of Product 4.0—products that convert the benefits of digital manufacturing into revenue and profit outcomes. Product 4.0 means your offerings open new revenue streams and are agile, responsive, cost effective and fast to market. Product leaders have the opportunity to assess how Product 4.0 can drive new customer and economic outcomes.

There are four important considerations for your strategy:

1. Cost

2. Revenue streams, especially new ones

3. Quality

4. Security

There are many digital manufacturing concepts, each supported by varying versions of technology and capabilities, software and hardware. The example we know best? Our own custom-built factories. Protolabs is a digital manufacturing company that was built within the framework of Industry 4.0 concepts nearly two decades ago. We wrote automation software and integrated it with connected manufacturing equipment to dramatically increase the production speed of prototypes and low-volume production runs. How we do this is certainly interesting, however, this paper is about converting digital manufacturing benefits into a viable Product 4.0 plan.

So, why do we suggest a Product 4.0 strategy? From the Protolabs perspective, serving global companies from large to small, there is intense product competition and mega trends driving the needs for responsive products. These trends include:

- The Internet of Things (IoT)

From home security to aircraft engines, there is a massive flood of new products and applications. We see them in nearly every industry.

- Mass Customization

Companies are customizing their catalog products, offering extensive accessories, and offering small custom product lines to win business. Their customers have many choices, so these companies customize to delight and win business.

- Short Product Cycles

Product life cycles continue to shrink, driven by electronics, customer taste, and competition.

Following the old norms of product development and supply chain management won’t necessarily allow product companies to meet these demands effectively. It’s worth the time and effort assess how leaders in various industries are adapting and if those adaptations support your business goals and those of your customers.

To frame the picture of Product 4.0, we’ll do so through the lens of the customers we serve. The CAD models that we’ve seen—all 4 million of them—tell a story. And through these stories common situations, benefits, and trends emerge that can help bring focus to your Product 4.0 strategy. We’ll look at data gleaned from global Product 4.0 pioneers ranging from innovative startups to the tech giants, and define considerations every product leader should contemplate.

Traditional vs. Digital Manufacturing

Let’s start by comparing the traditional manufacturing parameters and outcomes to those of the digital manufacturing capabilities inherent with Industry 4.0.

| Traditional Manufacturer | Protolabs Digital Manufacturing | |

|---|---|---|

| PROCESSES | Varied | Injection molding, CNC machining, sheet metal fabrication, 3D printing |

| PART LEAD TIME | Weeks to months | Within days |

| AVERAGE MOLD PRICE | >$20,000 | $5,000 |

| CAPACITY UTILIZATION TARGET | 100% | <80% (for responsiveness) |

| CAPACITY AVAILABILITY | First-in, First-out (FIFO), preferred customers, and largest orders placed highest in the queue | Infinite. Fixed lead times always honored. Order priority dictated by due date only |

| SCALE | Tens to hundreds of machines | Over a thousand mills, presses, printers, and other equipment |

| LOCATION AND COMMUNICATION | Local to international | In your region, time zone, language, and legal framework |

Digital manufacturing capabilities translate to speed, dependability, and deterministic outcomes, all of which feed nicely into Product 4.0. But you want concrete benefits, right? For the remainder, we’ll focus on the economics and implications of an injection molding process enabled by Industry 4.0 technologies. Of course, there are parallel benefits that may be applied to other digitized manufacturing processes.

Considerations for Your Product 4.0 Strategy

With an ecosystem at Protolabs of approximately 500,000 users serving as our foundation, we’ll dive deeper into the aforementioned considerations of a Product 4.0 strategy.

![]() 1. COST

1. COST

At Protolabs, our efficient, online business model drives lower cost. From insurance to retail, the digital disruptions of cost norms can be found in nearly every industry—manufacturing is no different. Digital accelerates processes, removes high-cost labor, and drives scale. How about an example to demonstrate the benefits to a product line P&L?

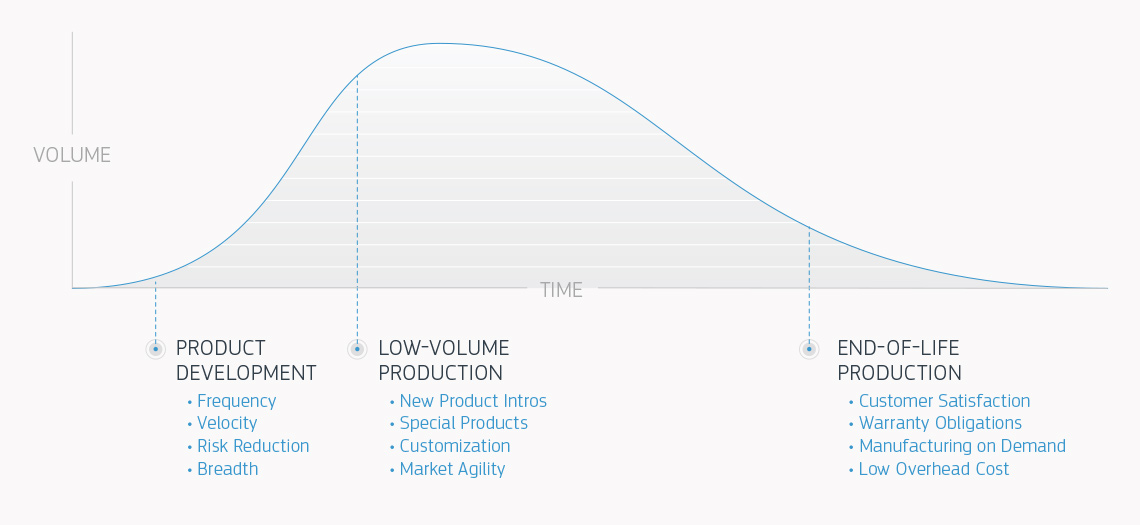

Take a device like a custom, handheld bar code reader. We’ll say it has five injection-molded components. While molding provides relatively low-cost parts, it brings the tradeoff of tooling costs that create a breakeven hurdle for new products. This hurdle is defined both by quantity of parts sold and the time it takes to sell them. Now imagine the product manager of the device would like minor design iterations on the product to meet new requirements dictated by market feedback after launch. In traditional manufacturing, upfront tooling investments may prohibit a second version of the handheld product, so the question becomes: How confident are you that market demand will justify your tooling investment and large part volumes? Here’s a typical breakdown:

| INJECTION MOLDED PARTS (5) | $5 |

| PROCESSOR AND DISPLAY | $100 |

| HARDWARE AND MECHANICAL COMPONENTS | $50 |

| ASSEMBLY LABOR | $50 |

| TOTAL UNIT COST | $205 |

| MARGIN | $50% |

| UNIT PRICE | $410 |

| OPERATING INCOME CONTRIBUTION (@15%) | $61.5 |

| TOOLING BREAKEVEN (IGNORING ALL OTHER FIXED COSTS | TRADITIONAL MOLDING | DIGITAL MOLDING |

| TOOLING PRICE | $20,000 * 5 $100,000 |

$5,000 * 5 $25,000 |

| UNITS TO TOOLING BREAKEVEN (IN CONTRIBUTION $) | 1,624 | 406 |

| YEARS TO BREAKEVEN AT 450 UNITS/YEAR | 3.6 | 0.9 |

![]() 2. REVENUE STREAMS

2. REVENUE STREAMS

If a factory is fast and flexible, how does that change the constraints and assumptions around revenue and profit? There are three ways we see leaders challenge the status quo:

A. Product Development Frequency, Velocity, Risk Reduction, and Breadth

Agile software development is a technique that focuses on short development efforts to deliver usable units of product. Deliver value early and often, goes the mantra. Major online retailers and enterprise software companies alike use frequent, fast iterations to test, learn, and deliver customer value. In this realm, physical product companies have not been able to compete. Timelines and hardware constrain iterations, the pace of innovation, and the number of concurrent programs.

What if prototyping was 10 times faster and the cost was 10 times lower? This is one of the core promises of 3D printing, which has expanded to a multi-billion dollar industry in the last few years. The principles of test, learn, refine, and iterate are now more accessible for hardware products. The same now applies to machining, molding, and sheet metal fabrication processes at Protolabs. What was once viewed as conventional, no longer carries with it that weighty reputation. One-day lead times for a new custom part? Unheard of before the advent of Industry 4.0.

Fast and flexible product development is thus a byproduct of Industry 4.0. From medical devices to electronics to automotive and aerospace components, companies within every major industry are applying agile concepts to their products. It’s a sink-or-swim landscape that gets more competitive each year. Common scenarios helping companies remain competitive and agile:

- Facilitating up to 10 product iterations to obtain and react to customer feedback

- Removing bottlenecks to increase product development project numbers or frequency

- Iterating to reduce cost and improve manufacturability

- Revising a product’s form, fit, and function before cutting expensive production tooling

Some development programs focus on risk reduction, others on customer delight. Most touch both. The point is digital manufacturing removes time and cost constraints for better performance and increased competition. Innovators are accelerating individual programs and leaders are driving efficiencies within all programs.

B. Revenue Opportunities with Low-volume Production and Mass Customization

The Protolabs version of digital manufacturing is optimized to low volume. Here, low volume means lifetime quantities typically between hundreds and tens of thousands of molded parts but more unconventional is the fact that the minimum part quantity is 25 pieces—a quantity normally deemed untouchable by high-volume manufacturers.

Now factor in the cost model from our first point with agility of low-volume production and the economic value of a digitally enabled injection molding model starts to take shape. So how can you use this cost reduction and low-volume agility to drive revenue?

Opening Revenue Streams at Different Product Phases

Let’s look at some common scenarios again:

- New Product Introductions

- Unknown initial market demand. Many companies have taken advantage of low cost tooling and responsive deliveries to test new offers in the market. A product 4.0 strategy can let hardware products behave like software products. “Test and learn” is the approach.

- Bridge tooling. Even for high-volume products that will inevitably sell tens of thousands or millions, a low-volume digital manufacturer can help you transition from prototyping to mass production. Even more use cases:

- React to surprise part orders or increased demand before launch

- Reduce time to market for boost competitiveness

- Address unexpected delays in production tooling caused by everything from technical approval to slow suppliers to labor disputes

- Specialty Products with Low Demand

- Avoid stocking thousands of parts due to minimum order quantities required by traditional manufacturers

- Respond to unpredictable consumer demand

- Achieve the lowest total cost (mold + parts), regardless of demand volatility

- Mass Customization

- Modifications of catalog products for key customers

- Develop unique product SKUs for specialty applications or niche markets

- Diversify accessories and add-ons to drive average sale prices

- Localize offers for global customers with different tastes, needs, and regulatory requirements

- Shorter Life Cycles of Manufactured Components

- Stay abreast to consumer trends and changes

- Maintain the pace of new tech

Be responsiveness. Say “yes” more often. It’s something most companies strive for and low-volume production enables. Need to tweak to the design of a catalog item to address customer concerns? Want to beta test a new market? Want to get your product in the hands of customer early? Respond to regulatory changes? Have a crisis? Generate early product buzz in the marketplace? This is Product 4.0. Savvy business leaders are applying these Product 4.0 concepts from Silicon Valley to the Motor City, and there are significant economic benefits for those who act.

C. End-of-Life Customer Satisfaction and Cost

We don’t meet many product managers and production managers that like end-of-life product planning. It’s emotional for customers and expensive for companies. There are outstanding warranty and support obligations while you’d prefer to reduce inventory.

Since Product 4.0 is about speed, responsiveness, and urgency, the growing trend of just-in-time (JIT) manufacturing to meet end-of-life and warranty obligations is being more widely adopted. One could even hypothesize that demand will grow as mass customization grows.

![]() 3. BENEFITS OF DIGITAL QUALITY MANAGEMENT

3. BENEFITS OF DIGITAL QUALITY MANAGEMENT

Quality is the price of admission for any manufacturer. Well-configured digital factories are poised to improve quality from part design to part production to final inspection and shipping.

Digital factories account for revision control and ensure outcomes meet customer requirements. Some, like Protolabs, work from 3D CAD models and an online configurable quote, eliminating reliance on often out-of-date prints. Yes, 2D modeling and paper prints are still around, though their time is limited. This is dated and inefficient protocol with Product 4.0. We see an elevated level of quality and accuracy in certain manufacturing processes when comparing an all-digital design environment to industry norms. For example, a digital thread with a traceable revision history ensures the product developer and manufacturer are working from the same version of the part design.

Other benefits:

- Utilization of CAD file PMI (product manufacturing information) data to eliminate 2D drawings and transcription errors

- Repeatable outcomes from automated g-code generation

- Uniform manufacturing equipment within and across vendor locations

The maturity of digital quality system vary. In selecting a digital manufacturing supplier, you should align manufacturing capabilities with your requirements.

![]() 4. SECURITY ACROSS DIGITAL SUPPLY CHAINS

4. SECURITY ACROSS DIGITAL SUPPLY CHAINS

If you upload your CAD model online, do you trust your CAD model and IP address to suppliers? It’s a valid security question that should not be taken lightly. Even though Product 4.0 requires you to enter a digital manufacturing realm, a range of policies and technologies are in place to protect your valuable IP. Remember when you started to pay bills online? Or bought product from an online marketplace? We’ve been there.

The key is to vet suppliers. Here are a few considerations:

- Strong and easy non-disclosure agreements

- Customer-friendly privacy policies

- Compliance with security standards such as Payment Card Industry (PCI) and the NIST Security Framework

- ITAR and Export compliance practices where applicable to your products

- Secure website

- Applicable laws and regulations

- Here is a subtle but powerful benefit of Industry 4.0. The solution for low-cost (but slow) molding over the last two decades was the use of low-cost labor in regions such as China. Working with an international supplier comes with a different set of cultural norms and policies on topics from IP protection to the environment. While many manufacturers in these regions are reliable, many are not. Industry 4.0 intrinsically on-shores manufacturing. Try to do business in your region, time zone, and language.

Summary

Every product leader should have an assessment plan and a defined position for each capability enabled by digital manufacturing. This article is one source that can help frame the path forward. Above all, we implore you—business and product line managers—to challenge yourselves with questions of current constraints and how applying the benefits of Product 4.0 can improve your product development cycles, revenue and cost outcomes, your company, and most importantly your customer’s outcomes.

About the Author

Dan Barsness is Vice President of Product Management and E-commerce at Protolabs, a digital manufacturer of custom parts for prototyping and low-volume production. He specializes in 3D printing, CNC machining, and injection molding technologies, and has served global industrial product development companies for more than a decade. Prior to Protolabs, Barsness spent eight years with MTS Systems, a leading provider of test and measurement systems, and has worked in customer-facing roles at two software startup companies and in the semiconductor industry. Barsness holds B.A. and B.E. degrees in Math, Physics, and Mechanical Engineering along with an MBA.