Aerospace 3D Printing

Reduce aerospace project and supply chain risk with reliable delivery, consistent quality, and a responsive team of experts

Certification + Compliance

ISO 9001:2015 | ISO 13485:2016 | AS9100D | ITAR

3D Printing for the Aerospace Industry

Speed, reliability, and quality compliance are key expectations of aerospace components. Our 3D printing services support demanding high requirement production scenarios by offering consistent and reliably fast lead times, expert design and manufacturability support, and an online platform for simple quoting and order placement.

3D printing enables aerospace engineers and product development teams to accelerate innovation across every stage of production. From early prototypes and testing components to end-use parts, additive manufacturing makes it possible to create lightweight, high-performance designs that meet the stringent standards of the aerospace and defense industries

How We Support Customers in the Aerospace Industry

|

|

Benefits of 3D Printing for Aerospace Components

| Additive manufacturing has become a cornerstone of modern aerospace engineering. From satellites and rockets to drones and cabin systems, 3D printing lets product teams design and manufacture parts that are lighter, stronger, and more efficient. |

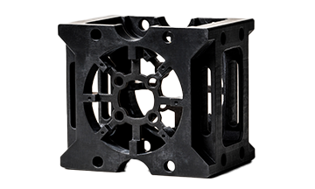

Lightweighting and Fuel Efficiency

Parts are optimized to use only the material needed, reducing mass while maintaining strength.

Design Freedom

Complex geometries and internal channels that can’t be machined are possible with additive manufacturing.

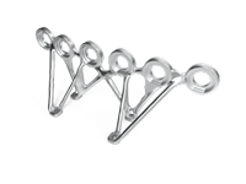

Reduced Assemblies and Paperwork

Fewer fasteners and part consolidations simplify traceability requirements, saving on costs and compliance burdens.

Faster Development Cycles

Quickly move from prototyping to production with industrial 3D printing capabilities.

3D Printing Processes for Aerospace Components

| Delivers exceptionally smooth surface finishes and fine details for cosmetic components and validation models. Hybrid PhotoSynthesis (HPS) technology combines the speed and accuracy of SLA and DLP for production-grade photopolymer parts. |  |

| Builds fully functional end-use metal components in as little as 7 days. Well-suited for high-value parts like manifolds, exhaust systems, turbo impellers, and rocket engine components. Ideal for consolidating multi-part assemblies into single components for simpler validation. |  |

| Produces nylon parts with consistent isotropic mechanical properties and fine feature detail. Commonly used for drone components and lightweight interior cabin parts. |  |

| Creates strong nylon-based parts without support structures, making it ideal for ducting, housings, jigs, and fixtures. Durable and flexible, SLS is a versatile solution for both prototypes and end-use parts. |  |

| Produces cosmetic prototypes and aerodynamic models with extremely high resolution and excellent surface finish. It’s commonly used for concept models, fit testing, and aerodynamic validation. |  |

3D Printing Materials for Aerospace Applications

| Aerospace-relevant materials are selected to balance strength, weight, and performance: |

Aluminum

High strength-to-weight ratio for housings, brackets, and thermal management components

Cobalt Chrome

Suited for engine exhaust and other extreme heat applications

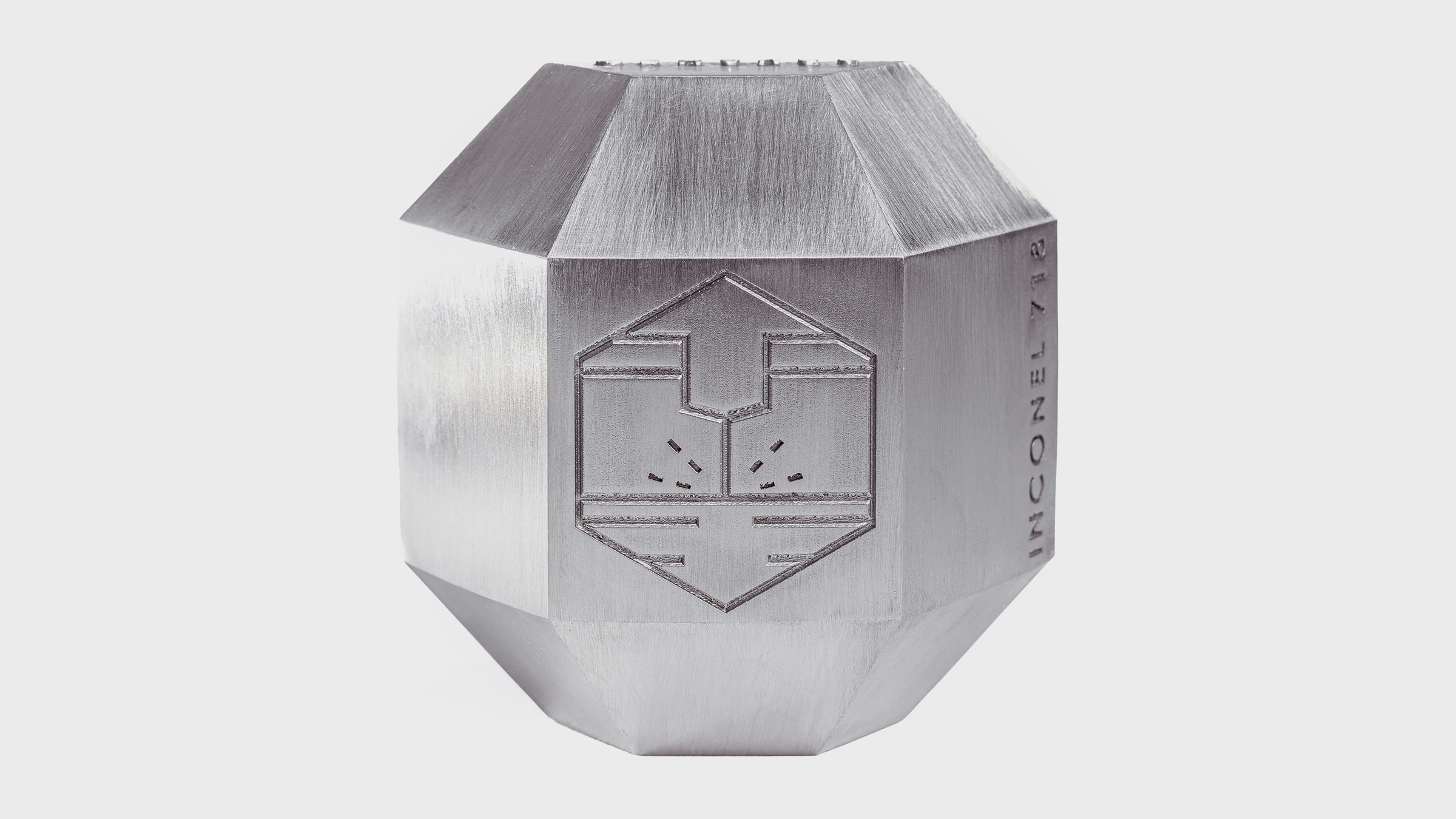

Inconel

A nickel-chromium superalloy with excellent high-temperature resistance, often used in rocket engines and exhaust systems

PA12 (via MJF)

A versatile thermoplastic for ducting, drone parts, and lightweight cabin applications

Silicone (fluorosilicone, optical)

High strength-to-weight ratio for housings, brackets, and thermal management components

Stainless Steel (17-4PH)

High strength and good corrosion resistance up to 600°F

Titanium

Lightweight and corrosion-resistant, ideal for satellite brackets and structural parts

3D Printing for Aerospace Applications

Additive manufacturing supports a wide range of aerospace applications, enabling designs that maximize functionality while reducing assembly and weight.

|

Performance 3D Printing for Aerospace

Additive manufacturing enables aerospace teams to move from concept to flight-ready parts with greater speed and precision. By combining advanced technologies with rigorous quality standards, 3D printing supports the production of reliable, high-performance components on demanding timelines.