Post-Processing for 3D Printing

Evaluate standard surface finishes for 3D-printed parts as well as advanced, custom finishing capabilities to improve durability, surface finish, and add color.

ISO 9001:2015 | ISO 13485:2016 | AS9100D | ITAR

We offer several surface finish and post-processing options for metal and plastic 3D-printed parts. These options can range from as-printed with only support structures removed to custom finishing for highly aesthetic parts.

Various post-processing operations can be used to:

- Reduce surface roughness

- Add custom color

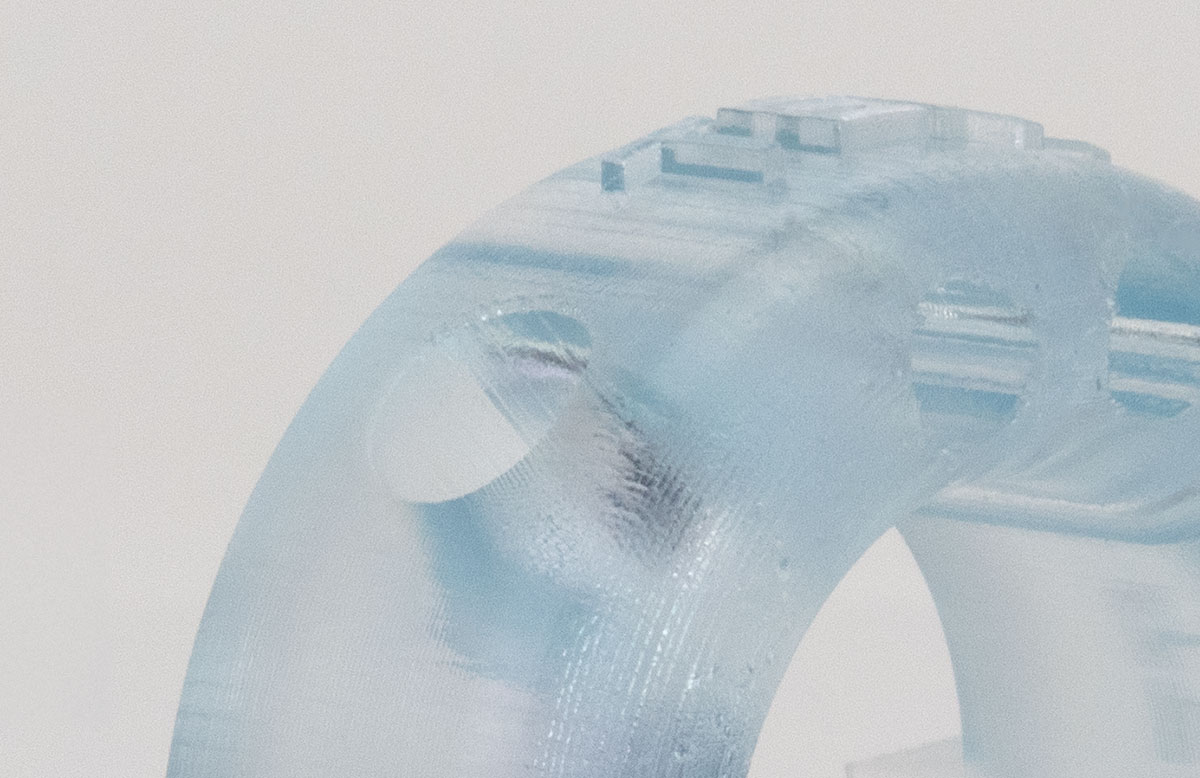

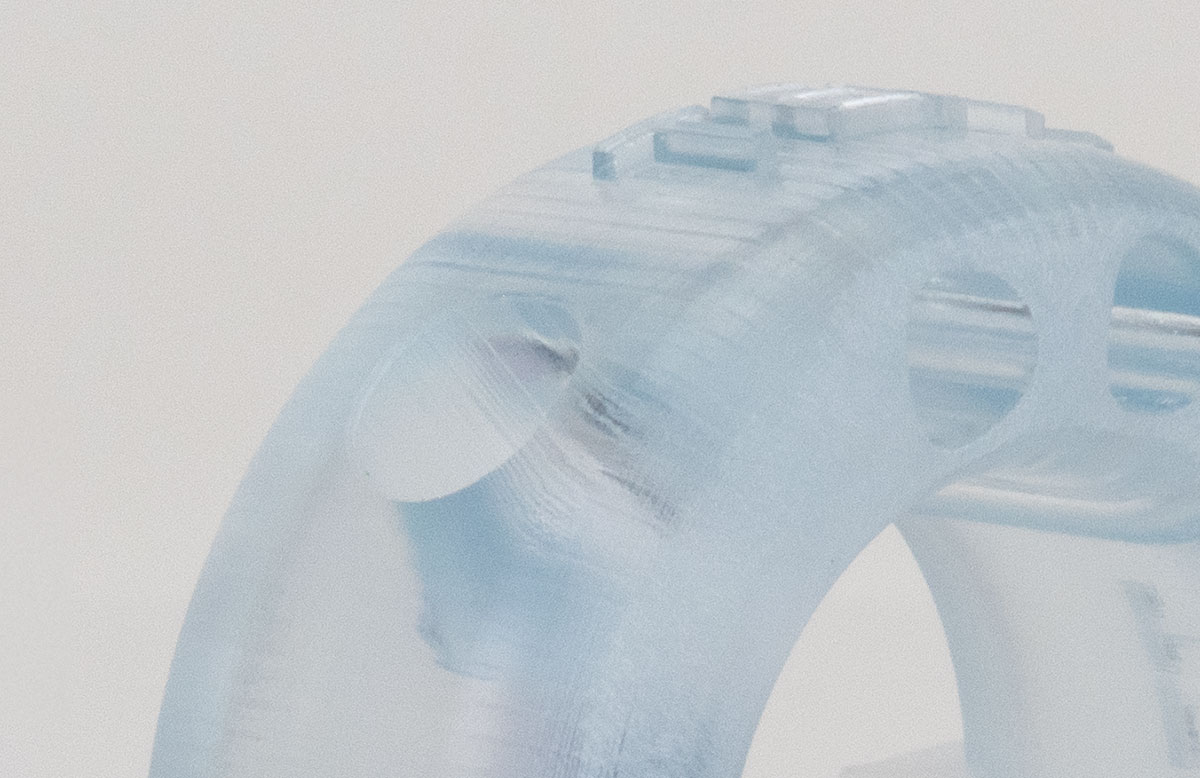

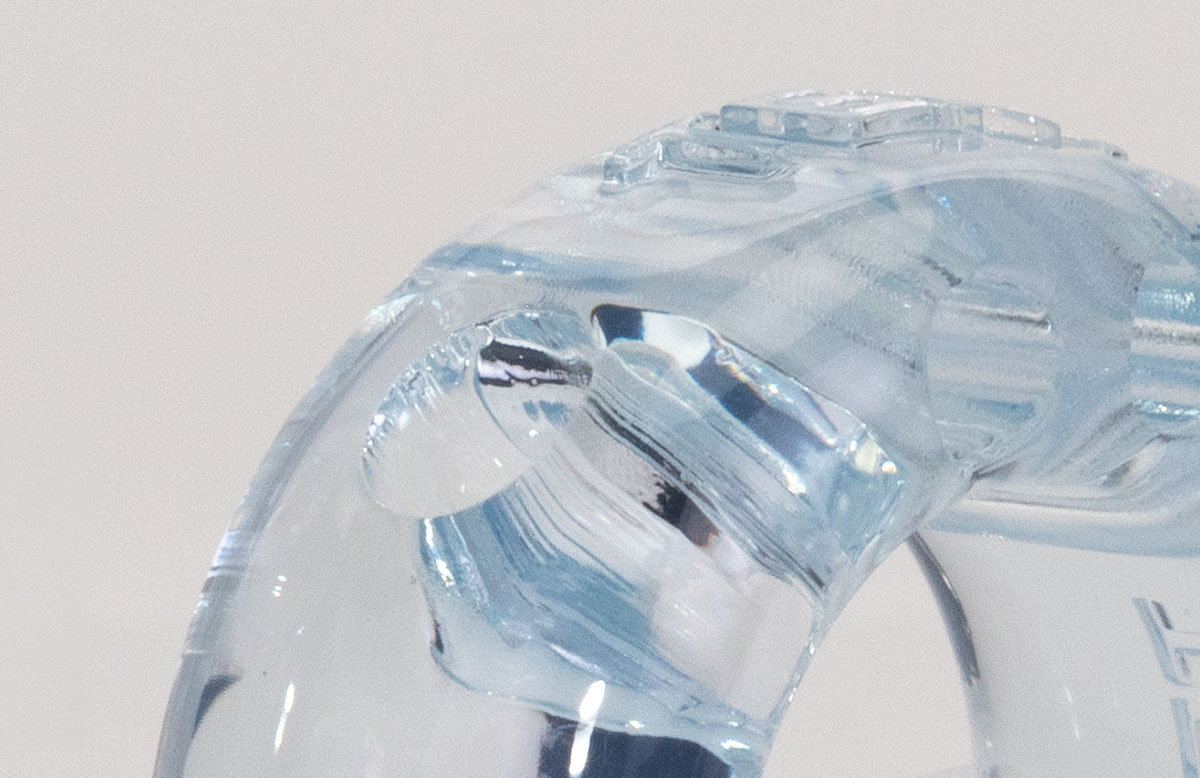

- Increase transparency

- Increase part strength

Note that finishing options will vary by material.

Print it BetterGet high quality 3D-printed parts fast with support from engineers who know additive inside and out. Build high-performing, reliable parts with six 3D printing technologies and 60+ materials. |

|

Custom

Soft-touch paint, clear part finishing, painting, masking, color matching, decals/graphics, and texture finishes are available. View custom options

Custom

Common post-processing options for MJF parts include a primer that can be applied, as well as taps and inserts. View custom options

Custom

Common post-processing options for MJF parts include a primer that can be applied, as well as taps and inserts. View custom options

Custom

Common custom finishing is clear coat on the digital clear material to enhance translucence. View custom options

Custom Finishing

Custom finishing options to meet your exact specifications are available.

| Plastics | |

|---|---|

| Clear Coat | Applied to plastic parts to create a clear, glossy finish. Ideal for lenses and other optical applications. |

| Thermal Cure | Enhance mechanical properties of Accura 5530 and PerForm. This process does make parts more brittle. |

| Plating | Electroless nickel plating adds strength and durability to plastic parts. |

| Painting | Parts can be painted to match any Pantone number. For best results, parts are typically sanded and polished before applying paint. |

| Dyeing | Dyeing is a low-cost option when a material’s natural color is not desired. Color options include black, green, red, blue, and yellow. |

| Texture | Apply a spray texture to mimic a Mold-Tech brand-like finish or improve UV-resistance of SLA parts. |

| Laser Engraving | Laser engraving can be applied to a raw 3D-printed part or a part that has been coated with Cerakote or paint. Laser engraving ensures crisp, consistent information on each part and great for logos, part numbers or serialization. |

| Metals | |

| CNC Machining | Achieve smooth surface finishes, tighter tolerances, or threading with post-process machining. |

| Cerakote | Cerakote is a high-quality, rugged coating for a wide variety of printed parts, independent of the printing process you choose. |

| Heat Treatment |

Multiple heat treatments are available to further enhance mechanical properties of metal additive parts. NADCAP certification is available upon request.

|

| Polishing | Brushed and polish surface finishes are available upon request. |

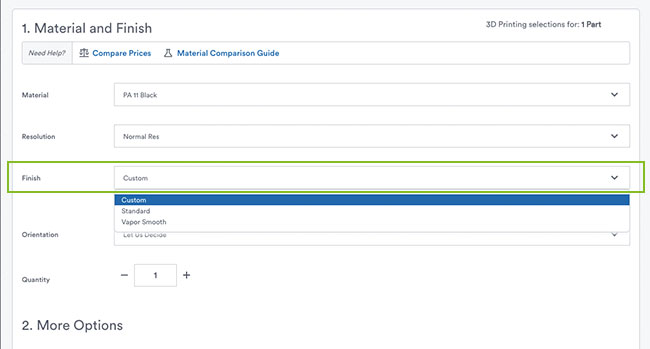

Step 1

In your quote configuration, select “custom” from the finish drop-down menu. From here you will be prompted to describe what type of finish you are looking for.

Step 2

By adding a request for custom finishing, this will trigger a manual review of a quote and an applications engineer will reach out to you to learn more about your part requirements and provide recommendations on a path forward.

Step 3

You will receive a link that will bring you to a final quote that includes the custom finishing required. Place your order and wait for your custom finished parts to arrive.