Advanced Photopolymers for 3D Printing

Our HPS technology delivers high-quality 3D-printed parts

Certifications ISO 9001:2015 | ITAR

Jump to Section

Beyond Prototyping

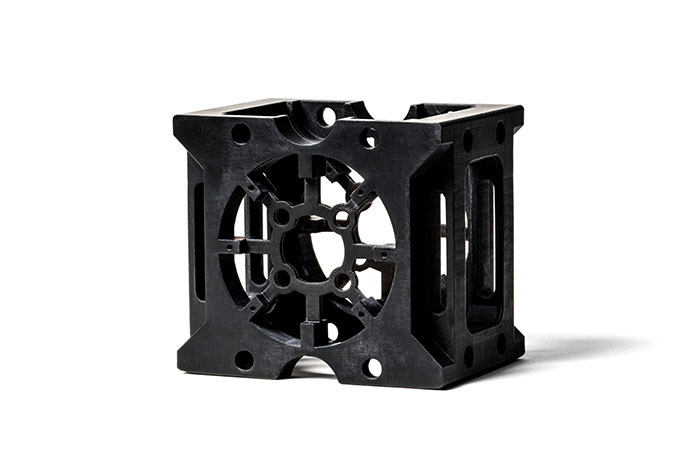

When your project requires advanced mechanical properties beyond stereolithography (SLA) and PolyJet, explore our advanced photopolymer materials unlocked by Axtra3D Hybrid PhotoSynthesis (HPS) technologies. HPS leverages the best features of Carbon digital light synthesis (DLS) printers, such as speed, near-isotropic parts, and smooth surface finish, but adds the greater speed and higher resolution of stereolithography (SLA).

Hybrid PhotoSynthesis (HPS)

HPS technology integrates both a precision laser and a digital light processing (DLP) system to simultaneously image internal and external structures. This dual approach allows the Axtra3D printer to overcome traditional limitations and produce exceptionally detailed parts with unmatched speed and quality.

Common applications for HPS are:

- High accuracy features for testing and validation.

- Production grade parts with excellent throughput.

- Glass-like surface finishes for cosmetic prototypes.

Compare Material Properties

| Material | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|

| Flame Retardant Black (Arkema FR512) | Black | 6.0916 ksi | 652.7 ksi | 4.2% |

| Tough Black | Black | 7.4 ksi | 262 ksi | 43% |

| Ceramic-Filled | Off-white | 12.6 ksi | 1,537 ksi | 1.30% |

| ESD Black (Loctite 3380) | Black | 6.5267 ksi | 420.6 ksi | 1.0% |

| Material | Color | Tensile Strength | Tensile Modulus | Elongation |

|---|---|---|---|---|

| Flame Retardant Black (Arkema FR512) | Black | 42 MPa | 4,500 MPa | 4.2% |

| Tough Black | Black | 51 MPa | 1,806 MPa | 10% |

| Ceramic-Filled | Off-white | 87 MPa | 10,597 MPa | 1.30% |

| ESD Black (Loctite 3380) | Black | 45 MPa | 2,900 MPa | 1.0% |

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

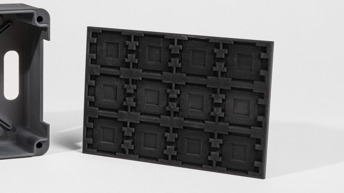

Surface Finish on HPS Parts

Unfinished

Dots, or standing nibs, remain evident on the bottom of the part from the support structure remnants.

Natural (Default)

Supported surfaces are sanded down to eliminate support nibs.

Standard

Supported surfaces are sanded, and the entire part is finely blasted for a consistent look. Note that the layers are still present.

Custom

Secondary options include a primer or paint that can be applied as well as taps and inserts.

How Does HPS Work?

One answer is fast—really fast. Two established technologies team up to create a sum that is greater than its parts. Like Carbon DLS, light is used to quickly harden liquid resin to create various geometries. HPS takes it a step further by adding a laser (as with SLA) to add precision and speed. When one layer is complete, the build platform rises and the process repeats until the part is complete. In the end, you get both the speed of Carbon DLS, and feature details, resolution, and build volume of SLA.