Aerospace CNC Machining

Reduce aerospace project and supply chain risk through reliable delivery, consistent quality, and a responsive team of experts

Certification + Compliance

ISO 9001:2015 | ISO 13485:2016 | AS9100D | ITAR

CNC Machining for the Aerospace Industry

Speed, reliability, and quality compliance are key expectations of aerospace components. Our CNC machining services support demanding low-volume, high-mix production schedules by offering consistently and reliable fast lead times, expert design and manufacturability support, and an online platform for simple quoting and order placement.

How We Support Customers in the Aerospace Industry

|

|

CNC Machining Processes for Aerospace Parts

CNC Milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts.

CNC Turning

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.

Protolabs Network

Our manufacturing network provides advanced CNC machining capabilities like tighter tolerances, volume pricing, and anodizing options.

Materials for CNC-Machined Aerospace Components

We have spent extensive time researching materials and canvasing our customers to better understand what materials matter most for the aerospace industry. That research yielded a curated list of materials that includes the most in-demand and functionally useful metals. Workhorse options like aluminum 6061—which is affordable and very strong compared to its weight—make up the bulk of the parts we machine, but we also offer a variety of steels, brass, copper, and even titanium for more demanding applications.

Designers know that reducing the weight of anything going into space—or even at lower jet flight levels—helps reduce fuel consumption, which adds up to substantial savings. There is a constant balancing of weight and strength in applications, and our available materials cover the vast majority of needs, even in early design and prototyping builds during which the end material might still be under evaluation. Engineers can build and test multiple versions representing multiple different material configurations all within the same platform and do so very quickly, finding the perfect material fit without losing excessive amounts of time.

Metals for CNC-Machined Parts

AluminumAluminum is a popular choice for machining due to its low density, good mechanical properties, high thermal and electrical conductivity, and resistance to corrosion. Aluminum alloys, such as 6061-T651, 7075-T651, and 2024-T351, are commonly used in CNC machining because they offer a good balance of strength, machinability, and cost. |

|

BrassBrass is an alloying consisting of both copper and zinc. The gold materials is a weather- and corrosion- resistant metal with tensile strength similar to mild steel. It's also an easy to machine material, so feedrates can remain high and coolant need is minimal. |

|

CopperCopper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile. Its glossy orange-reddish appearance is instantly recognizable, and the metal looks attractive even when it goes through a natural oxidation process that forms a bluish-green coating called patina in response to its environment. Note, however, that copper weldability is considered moderate to poor. |

|

Stainless SteelStainless steel is well-suited for a wide array of CNC machining projects, due to its excellent machinability and outstanding uniformity. It also has good workability and weldability to match your specific machining needs, as well as high ductility and formability to meet the specification requirements of any project. |

|

Steel AlloySteel Alloy 4140 is a low alloy steel containing chromium, molybdenum, and manganese. It is widely used across numerous industries and is an excellent material choice for machining due to its toughness, high fatigue strength, and abrasion and impact resistance. |

|

Steel Mild Low CarbonLow carbon steel, also known as mild steel, contains up to 0.30% carbon. This gives the material low strength while making it more malleable and ductile compared to high carbon steels. |

|

TitaniumTitanium is a popular material for CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. However, titanium presents unique challenges in machining due to its high strength, low thermal conductivity, and tendency to work harden during cutting. |

|

Plastic CNC-Machined Parts

While aerospace’s focus tends toward strong, lightweight metals, you might want to consider some plastics that offer various qualities consistent with industry needs. Acetals come to mind for particularly demanding mechanical applications, while Ultem and PEEK are great choices for high temperature applications.

Explore PlasticsCNC Machining for Aerospace Applications

| The aerospace industry relies on CNC-machined parts for a multitude of reasons. Two of the most important are accuracy and repeatability. In aerospace applications, parts are subject to extreme cold and heat, vibration, and massive pressure changes. CNC machining is commonly used to produce aerospace components such as: |

Brackets

Bulky angular designs are always a great fit for CNC machining. Brackets tend to be simple orthogonally based designs and CNC machining is great for that, although our sheet metal fabrication service might be a better way to go if the bracket is thin enough.

Engine Components

These critical parts must endure wear and tear, hostile environments, and require smooth, accurate geometries. Here’s an ugly scenario: Imagine an engine with pistons scraping across rough cylinder heads. CNC machining helps avoid that potential catastrophe. Confidence in these components withstanding significant forces and stresses is paramount.

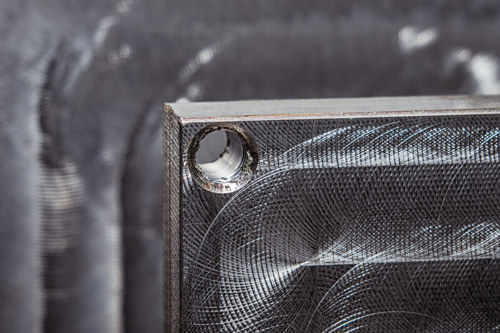

Heat Exchangers

These are good parts to manufacture on a CNC mill. The end mill can cut into solid blocks to create the fin-like structures you’re used to seeing. The fins provide extra area to assist with heat dissipation into surrounding air. Design these well and it’s possible to avoid the need for active cooling, such as fans.

Turbo Pumps

Another high-precision application for CNC machining, these spin thousands of times per minute. Typically, the impellers and blades are curved and must be made smoothly and accurately to ensure optimal aerodynamics and structural integrity. That’s where CNC machining shines.

Trends in Aerospace Design and Manufacturing

Historically, designers tend to think in terms of flat planes and orthogonal features (not to say there aren’t very complex aerospace parts out there). These designs fit very well with the machining process because design conception doesn’t differ much from the toolpathing that ultimately produces those parts (i.e., working in planes and relatively simple angles). That historical mindset means that much of the historical data available influencing modern designs is born from that same CNC-conducive angular approach providing a higher degree of confidence derived from past knowledge of how machined materials will respond under various conditions and strain.

With the emergence of artificial intelligence (AI), new design processes have emerged. In the NASA generative/AI projects we’ve supported, we produced parts with organic curvy designs that would appear far better suited for additive manufacturing than CNC machining. However, with NASA’s knowledge of Protolabs and our partnership, they were able to produce these organic, structurally optimized designs that are still compatible with our machining process, alleviating some of the concern that their finite element analysis (FEA) simulations might not properly capture if parts were made via a different manufacturing process.