CNC Machining Prototyping to Production

Choosing the Right Machining Service for your Product Development Needs

Where does CNC machining fit in your product life cycle journey?

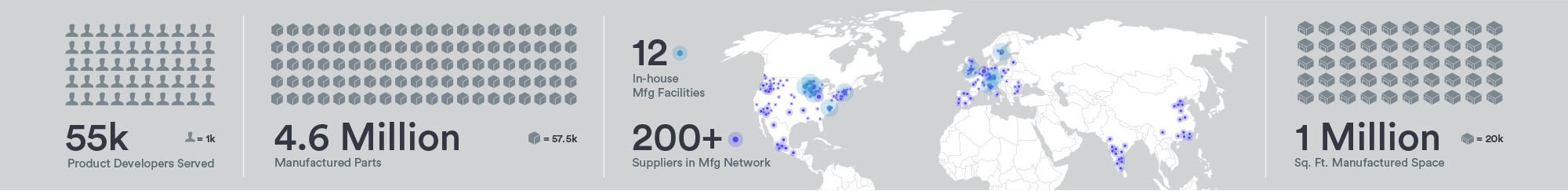

Our machining capabilities are unmatched. Our in-house, US-based factory provides fast and reliable local solutions, and our network of global and domestic manufacturing partners expands our machining capabilities with competitive pricing at higher volumes and tighter tolerances with greater material and finishing selections for end-use parts.

No matter what stage you’re at with your project—from initial iteration to production—we’ve got you covered. Let us help you find the right solution for your next machining project.

| CNC Machining | Automated Machining Factory | Traditional Machining via Global Network |

|---|---|---|

Get a Quote |

Protolabs | Protolabs Network |

| Lead Time | 1-9 days | 9-20+ days |

| Tolerances | Without technical drawing: +/-0.005 in. With technical drawing: Linear tolerance quoted to ISO 2768-1-1989-f, Standard hole tolerance quoted to +/-0.005” Hole & bore-style tolerance on specified feature may be +/- 0.0005 in. (+/- 0.0127mm) |

Auto-quoted linear tolerances as tight as +/-0.001 in. adhering to ISO 2768 standard. Tighter tolerances available upon review. |

| Compliance | ISO 9001, AS9100, ITAR | ISO 9001, AS9100, ISO 13485, ISO 14001, ISO TS16949 |

| Design Guidelines | Milling, Turning | Up to: 78 x 59 x 7.8 in. Larger envelopes upon review. Milling: Turning |

|

Materials |

40+ metals and plastics→ | 50+ metals and plastics→ |

| Threads |

Selection of UNF, UNC, and metric threads for machining. Can machine for threaded hole to accept coil insert, key insert, and Heli-Coil hardware installation. |

Standard thread tapping and milling. Can accommodate coil insert, key insert, and Heli-Coil hardware installation. |

| Installed Hardware | Without technical drawing no install and With technical drawing standard coil insert, key insert, and heli-coil hardware installation accepted. | Upon review of drawing |

| Secondary Operations | Extensive finishing and post-processing services including type II and type III anodizing, chromate plating, powder coating, AS9102 inspection, FAIs and Certificate of Conformance (CoC) documentation. Learn more |

Anodizing, chromate plating, bead blasting, EDM, EMA, and additional finishes available upon review. |

| Product Life Cycle | Ideation and Prototyping to End-use and Production | End-use and Production |

| Use Cases | Fast and reliable low-volume prototyping and service. | Complete end-use parts at economic prices to scale. |

| Required Upload | 3D CAD required, 2D drawings optional | 3D CAD required, 2D drawings optional |

Get a Quote |

Protolabs | Protolabs Network |

Still not sure which machining solution is right for your next project? Please call us at 877-479-3680 and we'll put you in contact with your account representative.

Leveraging Digital Manufacturing

Increase Speed to Market

- Quotes within hours, parts within days.

- Short manufacturing turnaround times support multiple design iterations.

- Development is accelerated and products are launched to market faster than before.

Design Better Parts

- Automated design for manufacturability (DFM) analysis provided free in every machining and molding quote, highlighting potential issues and providing immediate solutions.

- Application engineers available to discuss design challenges and offer support.

- Extensive library of online resources including guidelines, tips, and whitepapers.

Reduce Risk

- Cost-effective aluminum tooling validates design before capital investment in steel tooling is made.

- Manufacturing scale to relieve capacity issues and subsequent production delays for companies that are producing parts in-house.

- On-demand production to effectively manage demand volatility and inventory costs.

"Protolabs was able to help us through prototyping and iterating, then they helped us jump into the pilot production. It cuts down on surprises and miscommunication when you stay with the same supplier."

Related Resources