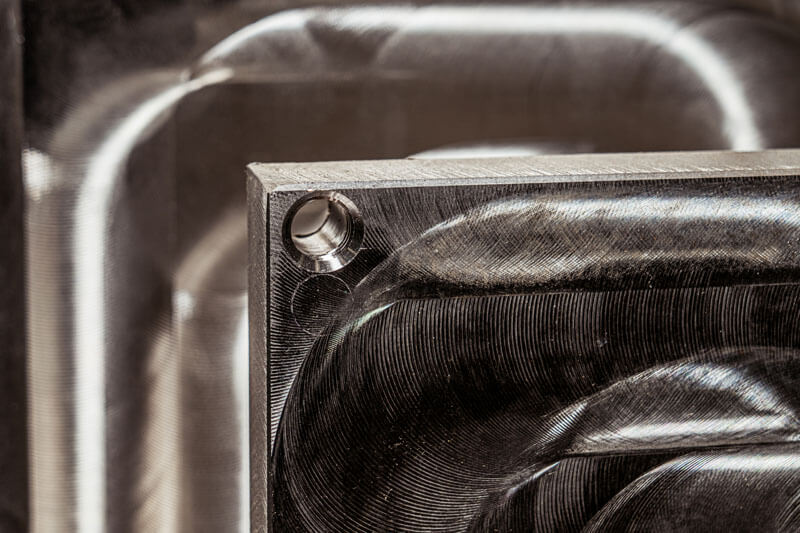

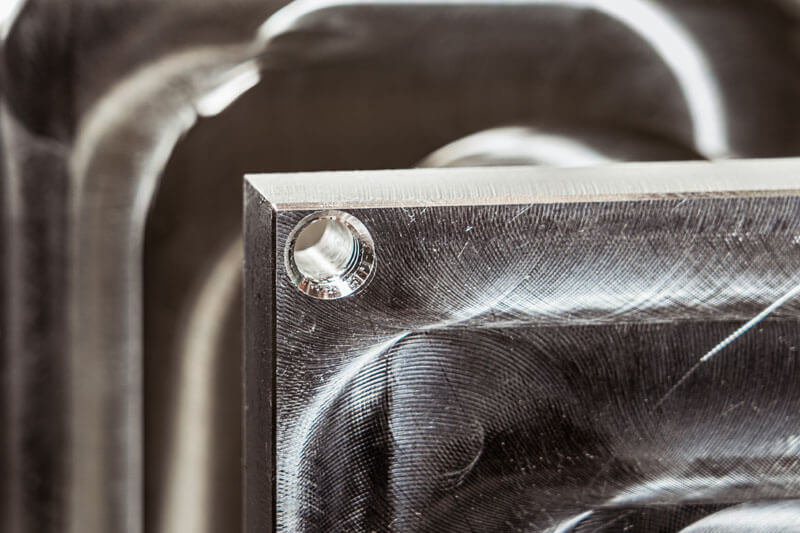

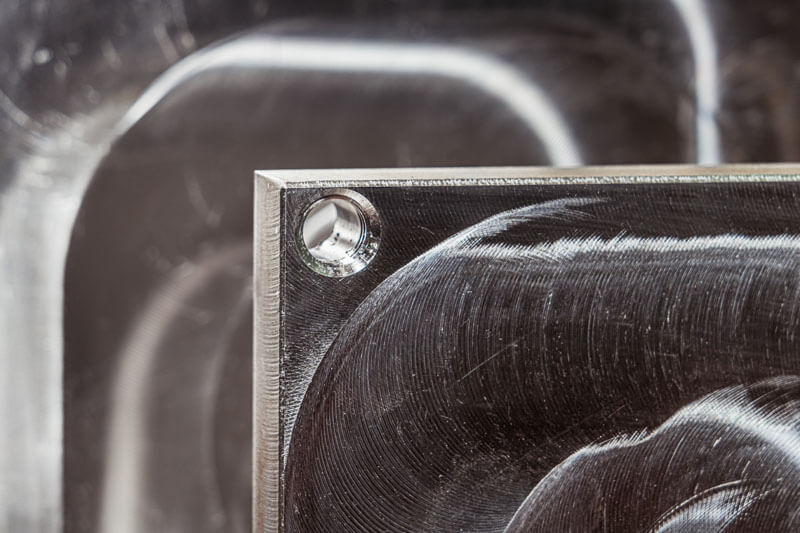

CNC Machining for Stainless Steel Parts

Stainless steel parts provide excellent machinability, workability, and uniformity, and are resistant to corrosion and oxidation

Get A QuoteWhat is Stainless Steel?

Stainless steel is well-suited for a wide array of CNC machining projects, due to its excellent machinability and outstanding uniformity. It also has good workability and weldability to match your specific machining needs, as well as high ductility and formability to meet the specification requirements of any project.

Stainless Steel Machining Applications

CNC machining of stainless steel is used to produce a variety of parts in the medical industry, robotics, food and beverage industry, aerospace, and any industry that requires high-strength applications. Stainless steel is an ideal material for applications such as:

- Medical instruments

- Machine parts

- Gears

- Parts for tractors

- Heavy construction equipment

- Vacuum and pressure vessels

Key Benefits

Stainless steel provides excellent machinability, outstanding uniformity, and is corrosion and oxidation resistant, leading to longer product life and lower total cost of machined parts.

- Corrosion resistance

- Designed for improved machinability

- Strong

- Low cost

- Quick part turn around

Compare Stainless Steel Alloys

We offer a variety of stainless steel options to suit any specifications or requirements. Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. Check out our material comparison guide for more information.

| Stainless Steel Alloy | Ultimate Tensile Strength | Elongation | Hardness | More Information |

|---|---|---|---|---|

| Stainless Steel 303 | 75-90 ksi | 35-50% | 228 HB | Data Sheet |

| Stainless Steel 304 | 99 ksi | 52% | 85 HRB | Data Sheet |

| Stainless Steel 316 | 85 ksi | 56% | 81 HRB | Data Sheet |

| Stainless Steel 17-4PH | 150 ksi | 8% | 33 HRC | Data Sheet |

Stainless Steel 303

Stainless Steel 304

Stainless Steel 316

Stainless Steel 17 4HP

Related Resources