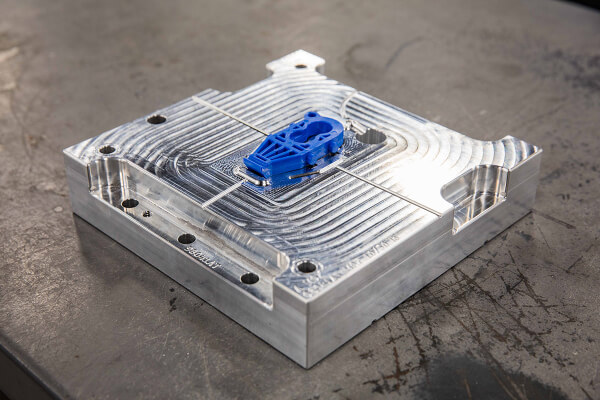

Small Parts Injection Molding

Have a small, simple part design? Get it injection molded within 7 days. Expedites available for parts in as fast as 1 day.

Guidelines for Standard 7-day Lead Time Parts

In order to qualify for 7-day standard lead time, injection molding designs must meet the below requirements. Have questions regarding your part design and meeting the requirements for a standard 7-day lead time? Schedule a design review with an applications engineer.

| Max Part Size | 3 in. x 2.5 in. X and Y extents |

| Geometry | Part design must not include undercut geometry that requires mechanical components like cams or inserts. |

| Materials | Thermoplastic resins |

Applications for Small Injection-Molded Parts

Parts that fit within our definition of small parts injection molding are common within the medical, consumer electronics, and automotive industries. Some example parts, include:

- plastic consumables

- connectors

- housings

- bushings

- bearings

Why Injection Molding at Protolabs?

| Automation | Knowing that the Protolabs process relies entirely on software, automation, and standardization is the key to understanding how best to leverage our services, from prototyping to production. |

| Speed | When you need parts fast, we can cut a new mold and deliver parts in as little as one business day. When you don't need them quite as fast, we deliver in as fast as 7 days. |

| Cost | Cost if a very important factor, and many of our customers value cost-effective tooling just as much as speed, depending on their unique strategies. Our robust aluminum tooling delivers an affordable options, while maintaining the quality needed for production programs. |

| Reliability | Scientific molding processes, automated in-line CMM inspection, FAI, and capability studies are just some of the in-process safeguards that we use to ensure high quality parts. |

Get Volume Pricing On Orders Over 50k Parts

Schedule a volume pricing consultation today

Resources for Designing Simple, Molded Parts

Check out the design tips below, for ideas on how to accommodate undercut functionality without the use of cams or inserts and meet requirements for standard 7-day lead times.