Sheet Metal Low Volume Production Service

- Get your full sheet metal bill of materials with a single vendor

- Expert technical and logistical support available

- Validate process quality with inspection documentation

- Respond to market demand with batch production

Certifications ISO 9001:2015 | ITAR

Talk with Our Production Team

Hello! We just need a few bits of information then a manufacturing expert will reach out to you directly to see we how can partner on a future production project.

Thank you! We've received your request and a member of our team will reach out shortly.

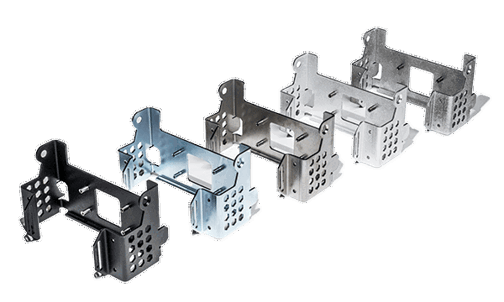

Production Capabilities for Sheet Metal Parts and Assemblies

Manufacturing Capabilities

Whether your production bill of materials includes simple designs, complex designs, or both, our fabrication capabilities can support your sheet metal geometries.

- Punching is a sheet cutting process which easily scales to higher volumes and can incorporate formed features in products such as panels, covers, enclosures, and housings.

- Bending offers the ability to include the intricate shapes often found in brackets, mounts, and chassis.

- Assembly of multiple sheet metal components provides a path for complex products such as weldments, sub-assemblies, and custom enclosures to smoothly transition you into production.

- Finishing options provide functional and aesthetic properties. Experts apply your finishing services with options including powder coating, plating, wet paint, masking, and silk screening. You can even combine multiple finishes, if needed.

Technical Support

We can help you navigate from design validation to pilot runs, and on to production using these technical tools:

- Our 3D-visualized design for manufacturability (DFM) analysis helps optimize your design to meet your production quality objectives. Also, it provides insights to simplify your designs, leading to cost savings. Learn more about navigating our sheet metal quoting and ordering process.

- Design for assembly (DFA) can aid in validating that a project can stand up to rigorous delivery reliability and quality benchmarks. Ensuring a design has adequate tooling access and clearance is one way to avoid challenges once full production launch occurs. Our team of applications engineers are standing by to support your design for assembly questions.

Schedule time to discuss your project today

Delivery and Logistics

Once you are ready to place a production order, our team supports you by reviewing your purchase order for any necessary quality clauses* and coordinates batch sizes and delivery schedules as needed.

*Note: Purchase orders with quality clauses may take additional time to process, which will extend turnaround of order confirmations.

Production Materials

We stock common sheet metal materials used for production part applications. Try our material comparison tool to help decide which material option is best for your project. The tool compares materials for formability, corrosion resistance, cost effectiveness, and more for the following materials:

- Aluminum 5052, 6061

- Brass C260

- Galvanized, Galvannealed (pre-plated steel)

- Low Carbon Steel CR 1008

- Stainless Steel 304, 316

Production Finishes

Our extensive finishing options help you match the exact requirements of your sheet metal component or assembly, no matter how complex the design or the finishes. These choices are designed to work with products that have either functional and/or aesthetic finish needs.

- Powder Coating

- Plating/Coating

- Wet Paint

- Silk Screening

- Masking

- Part Marking

Check out our menu of 100+ finishing options

Quality Processes and Documentation

Qualifying a supplier for production of a specific part number or SKU often requires an assessment of process quality. Our quality management system (QMS) ensures that your parts receive both in-process and post-manufacturing checks. Plus, our quality control experts review each batch for visual and dimensional accuracy.

Choose from the following menu of inspection documentation to get your own assessment of our quality processes at work:

- Dimensional Inspection Report

- First Article Inspection

- Certificate of Conformance

- Material Certification

- Finish Certification

Batch Production

Carrying and storing inventory is costly, particularly if demand forecasts are challenging to predict, such as when bringing new products to market. A common mitigation strategy for this situation is to stagger product deliveries, known as batch production, and avoid taking large volumes of inventory.

Our digital quoting system lets you easily configure production quantities. Once you receive the price and lead time for your desired quantity of parts, our team can work with you to translate that total quantity into batches. Instead of shipping the total quantity of parts to you in one shipment, we will work with you to identify an ideal batch size (sub-quantity of the total) and delivery schedule.

To move forward with your batch production order, contact our customer service team and provide the following information:

- Desired batch size (number of parts needed in each shipment)

- Desired shipping schedule/frequency (how often each batch should arrive at your location)