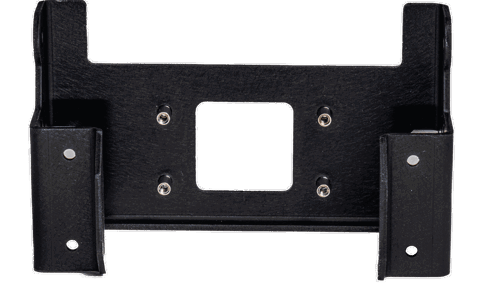

Sheet Metal Prototype Service for Components and Assemblies

Receive pricing and lead times for your designs in minutes and get precision fabricated prototypes delivered to you in just days. With every quote, we offer 3D-visualized design for manufacturability feedback, plus, you can validate part designs and transition to production with confidence.

Certifications ISO 9001:2015 | ITAR

Learn More about our Sheet Metal Prototyping Service

Why Protolabs?

Quotes delivered in minutes and parts in days

We quote and manufacture both simple and complex sheet metal designs in a fraction of the time of traditional methods. Upload, configure, and order your parts on Monday and they are on your desk by Friday.

Repeatable process quality

Our fabricators have decades of experience in producing high-quality sheet metal components and assemblies, ensuring that you and your stakeholders can evaluate an accurate representation of your design. Learn more about how we safeguard part quality.

Manufacturability analysis on every design

Leverage our sheet metal design for manufacturability (DFM) analysis tool for 3D-visualized insights into potential manufacturing challenges and identify opportunities to optimize your design for speed and cost.

Capacity to produce thousands of unique designs every month

We fabricate thousands of unique sheet metal designs of all shapes and sizes each month. Our automated process provides on-time delivery reliability, so your shipment arrives on time.

Advanced design support for assemblies and complex projects

Our team of applications engineers are trained sheet metal experts who are available to consult with you on all aspects of your design. Whether you're looking for advice on feature placement, tooling selection, or assembly construction options, we answer your questions in a free 30-minute virtual session. Schedule your session today.

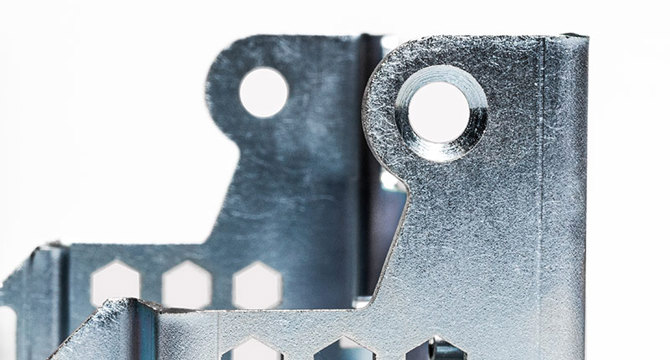

Sheet Metal Capabilities

We have a broad selection of sheet metal fabrication capabilities for your prototype components and assembly projects. Our collection of manufacturing processes gets you simpler flat geometries, intricate formed parts, and complex welded assemblies at unparalleled speeds.

Explore our capabilities:

→ Laser cutting

→ Punching

→ Forming & Bending

→ Hardware insertion

→ Welding

→ Assembly

→ Finishing

How Our Lead Times Work

Our digital sheet metal fabrication service delivers components and assemblies to you in just days. Review the tool below to see how your precision quality parts would qualify.

Sheet Metal Lead Time Map

| Fabrication Capabilities | Eligibility | Applications |

|---|---|---|

|

Material thicknesses: ≤0.125 in. (≤3.175mm) |

|

| Fabrication Capabilities | Eligibility | Applications |

|---|---|---|

|

All material thicknesses: 0.024 in. - 0.250 in. (0.61mm-6.35mm) |

|

| Fabrication Capabilities | Finishing Options | Applications |

|---|---|---|

|

|

|

Advantages of Prototyping with Sheet Metal Fabrication

Validate your design cost-effectively

Before transitioning your design to higher up-front investment technologies such as hard tooling, sheet metal fabrication provides a cost-effective way to validate functionality and the physical or mechanical properties of your design before you freeze it for end-use production.

Highly customizable processes produce many types of geometries

Complex product applications often require sheet metal parts of various shapes, sizes, and feature sets. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs.

Simulate your design with a real-world analog

Depending on which certifications might be needed to bring a product to market, sheet metal fabrication can produce a design for testing purposes. Doing that comes with the added benefit of avoiding high up-front tooling costs. Machine set-up costs are quickly amortized with each incremental unit fabricated.

Abundance of design flexibility and avenues for cost optimizations

Like many manufacturing technologies, sheet metal fabrication is no stranger to trade-offs. While sheet metal offers a high degree of design flexibility, design simplification can yield significant cost savings. For example, moving a hole or cutout a fraction of an inch away from a bend line could amount to sizeable savings by eliminating costly CNC machining or hand drilling operations.

Product Applications for Prototyping

Sheet metal fabrication is a collection of manufacturing processes that can produce geometries of all shapes and sizes. In practical terms, this means it can fulfill the needs of many types of products, such as:

| Generic Products | Specialized Applications |

|---|---|

|

|